Wet Etching Resist

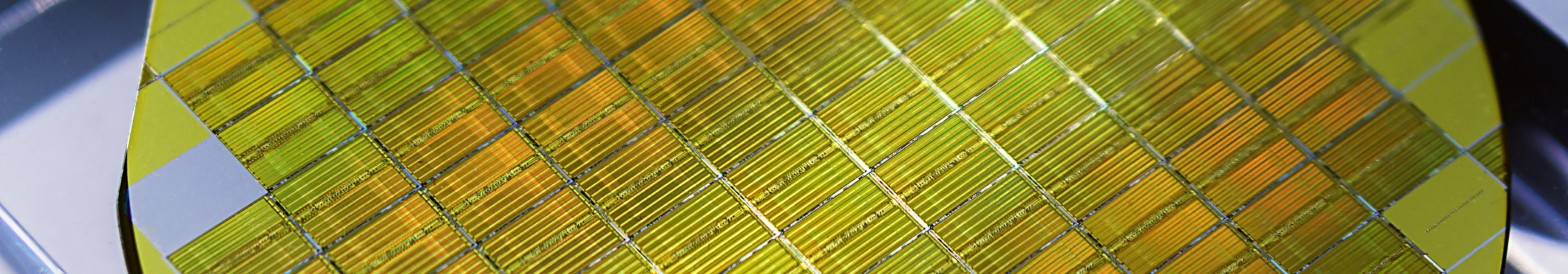

Negative Resists Resistant to Both Acidic and Alkaline Etchants

We offer rubber resists that are resistant to both acidic and alkaline etchants, as well as g-line, i-line, KrF positive and negative photoresists that enable fine pattern formation by wet etching with acidic etchants.

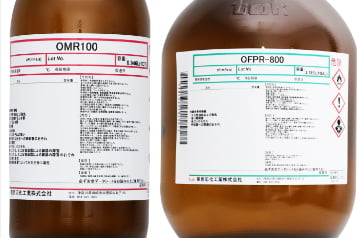

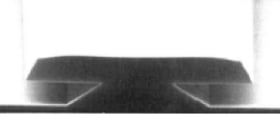

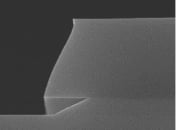

Rubber-Based Negative Resist

This is a rubber-based negative resist that is resistant to acidic and alkaline etchants. The use of a rubber-based resin as the main raw material provides excellent adhesion and chemical resistance, making it suitable for long-time wet etching processes and reducing the amount of side etching compared to Novolak-based positive resists.

Rubber-Based Negative Tone Type

Application Conditions

Substrate

SiO₂ (700nm)

Resist Thickness

1.0μm

Pre-bake

80~85℃, 20min (warm circulating dryer)

Exposure

G/I/H Broadbent Exposure System

(11.0mW/cm2 405nm)

Post-bake

145±5℃, 20-30min (thermal mechanical dryer)

Development and Rinse

OMR developer, OMR rinse solution

| Etching Conditions HF:NH4F 23℃, 5min |

|

|---|---|

| 5.0μm Line Pattern |  |

OMR in the text is a pending or registered trademark of TOK.

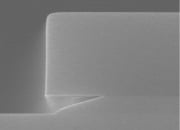

G-Line Positive Resist

A positive photoresist based on g-line Novolak resin with improved adhesion to substrates. It is suitable for wet etching with acid-based etchants. Compared to rubber-based negative resists, it has superior resolution, enabling wet etching of fine patterns.

Novolak Positive Tone Type

Application Conditions

Substrate

SiO₂

Pre-bake

90℃, 90sec

Exposure

g-line stepper

Post-bake

120℃, 5min (oven)

Development

NMD-W 2.38%, 65sec

| Etching Conditions HF:NH4F = 1:6 23℃, 20min |

|

|---|---|

| 5.0μm Line Pattern |  |

OFPR in the text is a pending or registered trademark of TOK.

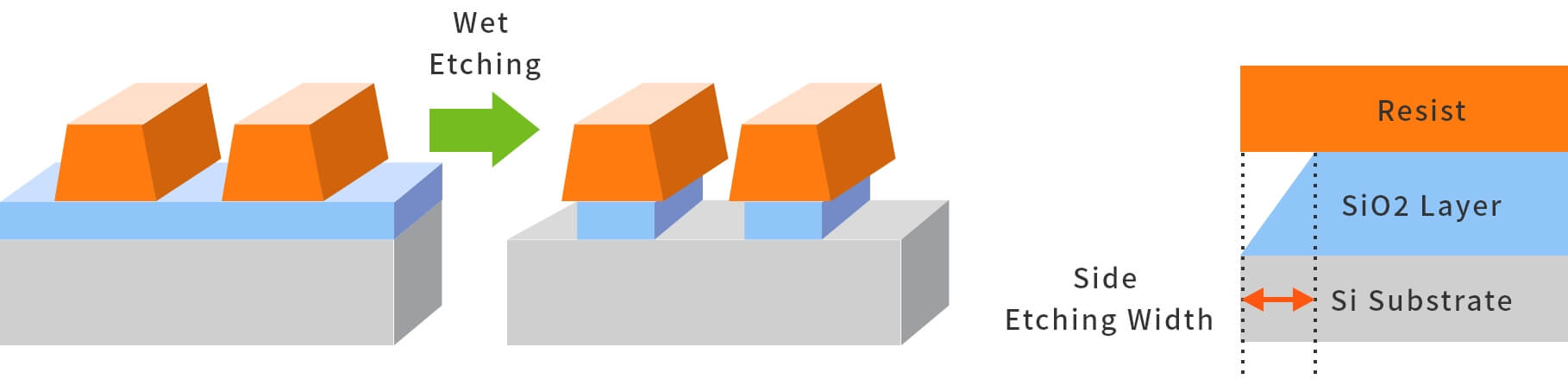

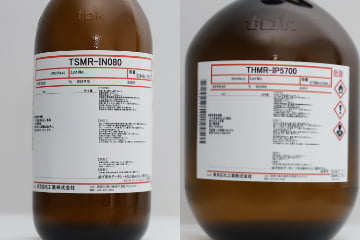

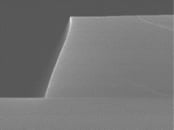

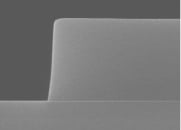

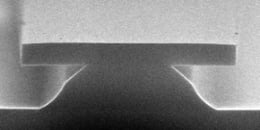

I-Line Positive Resist THMR™-IP5700 ∕ I-Line Negative Resist TSMR™-iN080

We offer both positive tone and negative tone i-line resists that are suitable for wet etching and have excellent substrate adhesion.

Application Conditions

Substrate

SiO₂ (HMDS treatment, 110℃, 60sec)

Resist Thickness

5um

P.A.B.

90℃, 120sec

Exposure

i-line stepper (NA: 0.57, σ: 0.67)

P.E.B.

110℃, 60sec

Development

TMAH 2.38% paddle 60sec

Post Bake

100℃, 60sec

Etchant

BHF (NH4F・HF 21%aq.)

Etching Time

12min

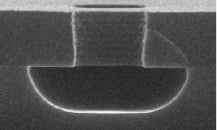

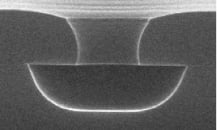

| THMR-iP5700 | TSMR-iN080 | |

|---|---|---|

| Profile After Patterning |  |

|

| After Wet Etching |  |

|

| Side Etching Width | 2.61μm | 3.34μm |

THMR and TSMR in the text are pending or registered trademarks of TOK.

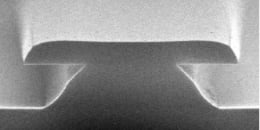

KrF Positive Resist TDUR-P802

The resist is designed for fine processing in high-resolution KrF wet etching processes with high resistance to etching agents and adhesion to the substrate. The resist is designed for use in wet etching after KrF lithography for sub-micron pattern sizes that cannot be achieved with i-line resists.

TDUR-P802 Resolvability

Application Conditions

Substrate

SiO₂ (HMDS treatment, 110℃, 60sec)

Resist Thickness

510nm

P.A.B.

110℃, 60sec

Exposure

KrF stepper (NA: 0.68)

P.E.B.

110℃, 60sec

Development

NMD-W 2.38%, 60sec

| 200nm Space | |

|---|---|

| EOP:13.0mJ |  |

TDUR-P802 Wet Etching Properties

Application Conditions

Substrate

SiO₂ (HMDS treatment)

Resist Thickness

510nm

P.A.B.

110℃, 60sec

Exposure

KrF stepper (NA: 0.68)

P.E.B.

110℃, 60sec

Development

NMD-W 2.38%, 60sec

Etching

HF:NH4F = 1:6, 660sec

| Resist Thickness 518nm | ||

|---|---|---|

| Post-bake | 110℃-300sec | 130℃-300sec |

| 5.0μm Line Pattern |  |

|

| Side Etching Width | 3.02μm | 2.90μm |

| 600nm Contact Hole |  |

|

| Side Etching Width | 1.02μm | 0.96μm |

TDUR in the text is a pending or registered trademark of TOK.

Please Feel Free to Contact Us for More Information

For any questions or concerns,

Send an Inquiry Through the Web

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.