Bump Formation Resist

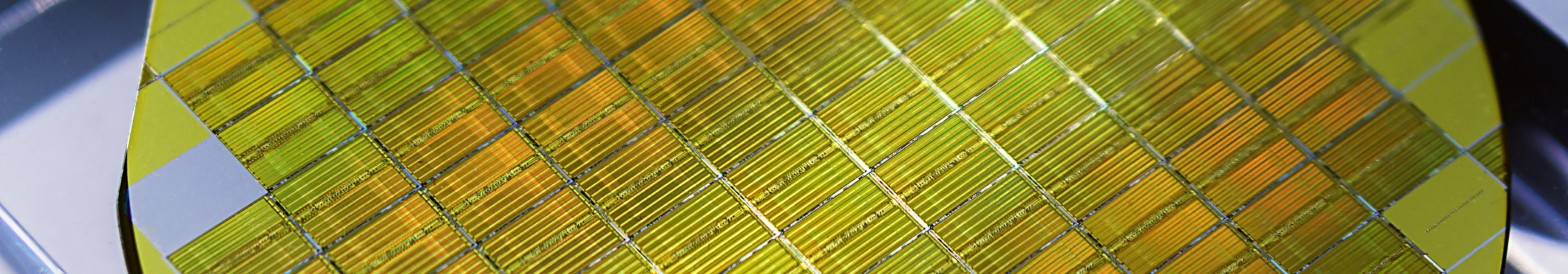

Resist for Photobumping for Copper, Tin, Nickel and Solder Electrolytic Plating such as Au Bumping, Cu Pillar and Microbumping

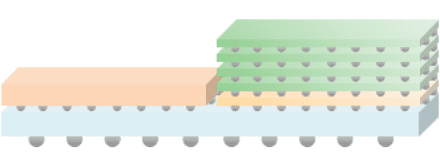

This type of resist is used in high-density semiconductor packaging for 2.5/3D through-silicon packages, TSV stacked memory, WL-CSP (wafer-level chip size packages), Cu pillar/Philip chip packages and LCD driver microbumps/monstat bumps/Cu posts. It is a high-resolution positive thick film resist for electroplating that is resistant to non-cyanide metal, silver, tin, copper, and nickel plating solutions.

This type of resist is capable of forming fine hole patterns with high sensitivity. The resist has a high adhesion to the substrate and a high process margin in the plating process, and can be easily removed after the plating process compared to negative resists. This makes it possible to reduce the cost of the bump electrode formation process. A wide range of resists are available for various thicknesses from 10~100µm. We offer a wide range of process materials for high level semiconductor packaging technology such as SiP (System in Package) and PoP (Package on Package).

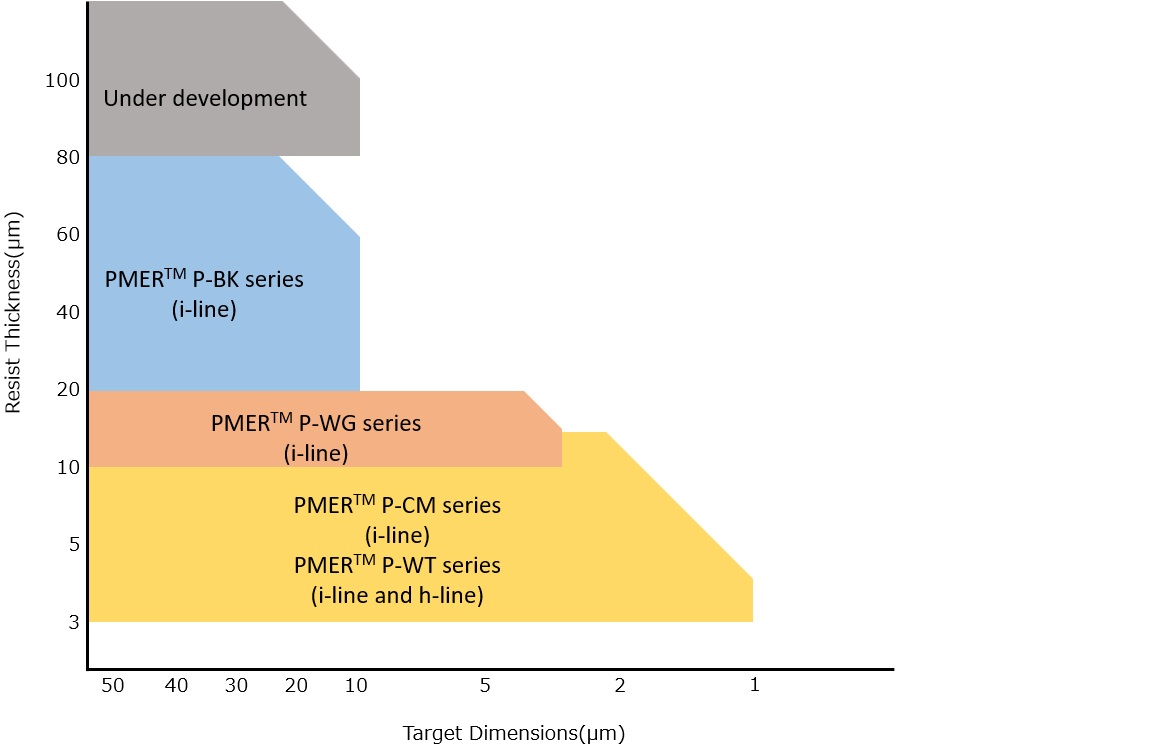

Electrolytic Plating Photoresist Lineup

Photoresist for Cu Pillars and Microbumps

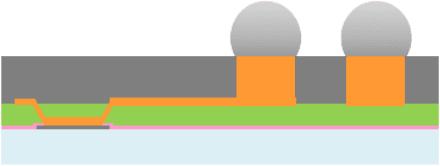

Cu Pillar Bump, Sn/Ag Bump, Microbump Formation

PMER P-BK4000

This is a positive photoresist for the plating process with high resolution and plating solution resistance, and has been designed to meet the needs of the most demanding applications such as Cu Pillar BGA and TSV memory microbumps. This system can be used for electroplating of Cu, Ni and SnAg. The resist can be easily removed after the plating process without damaging the electrode. This product is available in a variety of viscosities for resist thicknesses from 20~65μm.

Features

- Positive tone type

- Developer: NMD-3 2.38% (TMAH 2.38%)

- Resist film thickness: 20µm〜65µm

- Wide process margin & crack margin

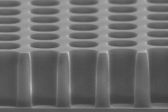

- Rectangular shape & good peelability

Conditions

Sample :PMER P-BK4000Substrate :Cu sputtered water (Cu/Ti 3500A/1000A)

:EBR-1000±300um

PAB :145dC-300s

Exposure :Canon FPA-5510iV (NA=0.18)

PEB :85dC-180s

Development :TMAH 2.38%, 60s X 4, 6 puddle

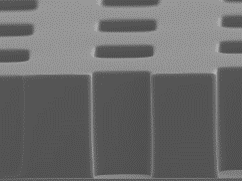

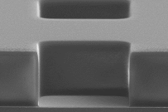

Resist Profile

| S/H 30μm | S/H 20μm | S/H 10μm | |

|---|---|---|---|

| Resist Thickness 65μm |

|

|

|

PMER P-BK2000

This is a positive photoresist for the plating process with high resolution and plating solution resistance, and has been designed to meet the needs of the most demanding applications such as Cu Pillar BGA and TSV memory microbumps. This system can be used for electroplating of Cu, Ni and SnAg. The resist can be easily removed after the plating process without damaging the electrode. This product is available in a variety of viscosities for resist thicknesses from 20~65μm.

Conditions

Sample :PMER P-BK2000Substrate :Cu sputtered wafer

Film thickness :20~30um

PAB :145dC-300s

Exposure :Canon FPA-5510iV (NA=0.18)

Mask :5~20 umCD (1:1.5)

PEB :85dC-180s

Development :TMAH 2.38%, 60s x 4puddle

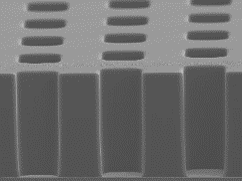

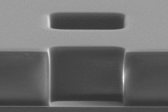

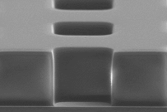

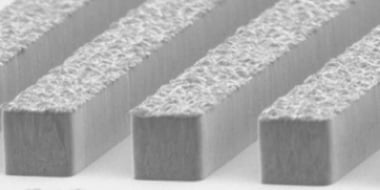

Resist Profile

| Line / Space | S/H 25μm | S/H 20μm | S/H 15μm | S/H 10μm | S/H 5μm |

|---|---|---|---|---|---|

| Resist Thickness 20μm |

|

|

|

|

|

PMER P-CS Series

This series of resists can be used for precious metal plating processes such as gold and palladium, and has high resistance to metal plating solutions.

Features

- Fine gold plating

- Positive tone type

- Suitable film thickness range = 10~20μm

Photolithography Conditions

Substrate

Au

Film Thickness

20μm

Gold Plating Conditions

Pretreatment

O2 plasma ashing

0.15torr, 300W, 40℃, 60s

Plating

Cyanide gold plating solution

Resist Stripping

TOK's resist stripper ST120

Pd Plating Conditions

Plating Solution Type

Pd plating solution pH = 7.5

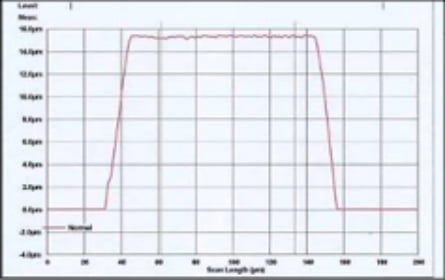

Plating Conditions

1.5ASD 50℃, 48.6min

Pd Plating Thickness

18um

Resist Stripping

ST-120, 45℃, 10min

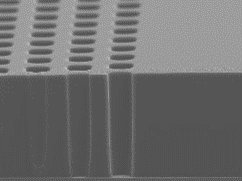

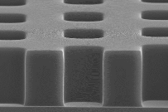

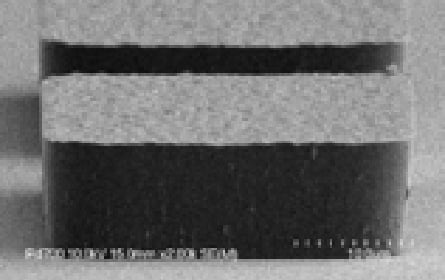

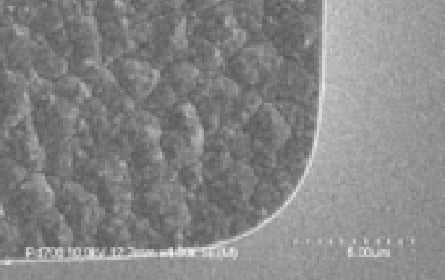

Gold Plating Shape After Resist Removal

| L/S=20/20μm | 20μm Square Pillar Plating Shape |

|---|---|

|

|

Palladium Plating Shape

Please Feel Free to Contact Us for More Information

For any questions or concerns,

Send an Inquiry Through the Web

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.