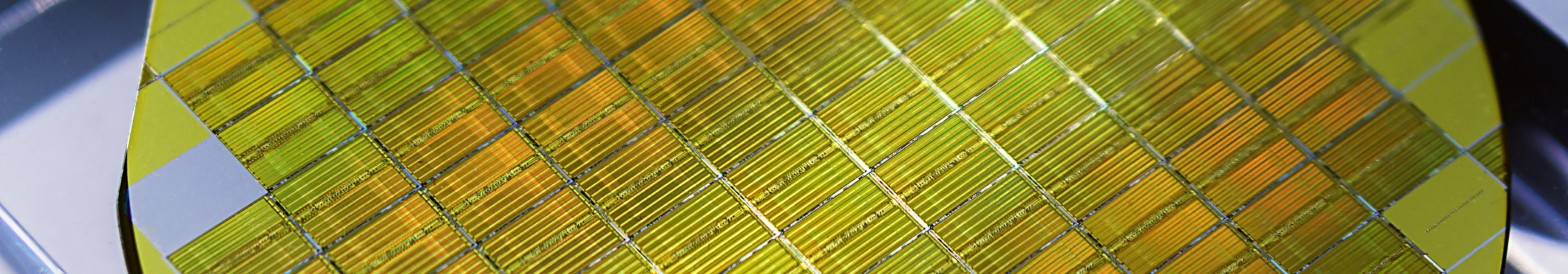

KrF Resist

Development of Chemically Amplified Resists

Compatible with 248nm Laser

Since the latter half of 1990, we have been developing chemically amplified resists that are compatible with 248nm long krypton fluoride (KrF) laser light sources. Throughout these years, we have been offering a wide range of products such as positive type, negative type, and thick film type to meet the various needs of our customers.

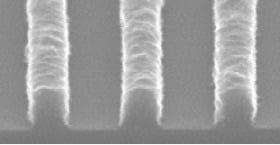

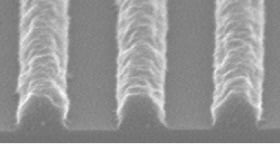

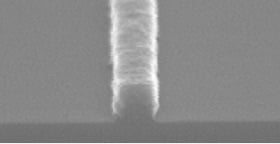

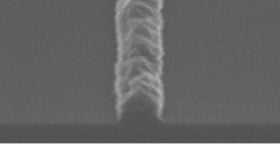

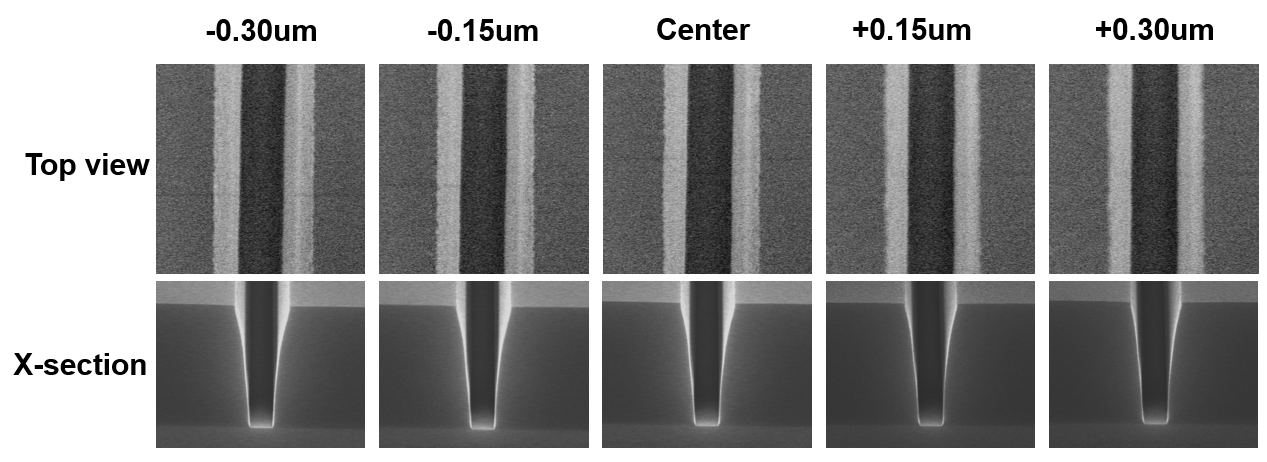

Positive KrF Resist for Lines

This resist was designed and developed for line formation. It is used in a wide range of applications including metal and implant applications.

TDUR™-P3435

Conditions

Substrate

Si with HMDS

Resist Thickness

250nm; (Nf:1.56 at 633nm) /

190nm; (Nf:1.56 at 633nm)

Pre-bake

100℃, 60sec

TARC

TARC 44nm (RI=1.44 at 633nm)

TARC Bake

60℃, 60sec

Exposure

KrF stepper (NA: 0.75, σ: 0.60)

P.E.B

110℃, 60sec

Reticle

TOK-248-010 (6% half tone)

Development

NMD-3 2.38%, 23℃, 60sec, LD nozzle

Post-bake

100℃, 60sec

Target

Target CD: 150nm line

(Mask: 150nm, Pitch: 330nm)

Overview

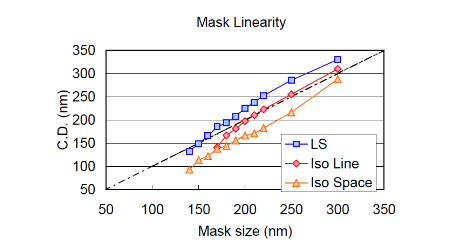

| TPR=250nm | TPR=190nm | ||

|---|---|---|---|

| Profile | LS |  |

|

| ISO |  |

|

|

| Trench |  |

|

|

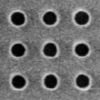

Positive KrF Resist for Holes

This resist was designed and developed for hole formation. It is used in various processes including contact hole formation.

TDUR-P4197T PM

Substrate

BARC

Film Thickness

430nm(R.I.:1.56@633nm)

Pre-bake

90℃, 60sec

Exposure

KrF stepper (NA: 0.75, σ: 2/3 annular)

Mask

TOK Reticle (HT 6%)

P.E.B

110℃, 60s

Development

NMD-3 2.38%, 60s, Paddle

Target: Hole/Mask/Pitch = 123/150/300

| -0.20 | -0.15 | -0.10 | -0.05 | 0 | 0.05 | 0.10 | |

|---|---|---|---|---|---|---|---|

| TPR:340nm Exp:75mJ/cm2 |

|

|

|

|

|

|

|

| TPR:430nm Exp:79mJ/cm2 |

|

|

|

|

|

|

|

| TPR:520nm Exp : 86mJ/cm2 |

|

|

|

|

|

|

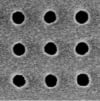

Negative KrF Resist

A wide range of KrF resists are available for the photolithography and post process applications that require properties of negative type resists.

TDUR-N Series

Substrate

BARC

Resist

TDURTM-N Series

Film Thickness

400nm (Nf:1.58)

Pre-bake

90-100℃, 60sec

Exposure

KrF stepper (θ: 2/3 annular)

P.E.B.

110℃, 60s

Reticle

HT 6%

Development

NMD-3 2.38%, 60s

| TDUR-N Series 38mJ / cm2 |

TDUR-N Series 38mJ / cm2 |

TDUR-N Series 38mJ / cm2 |

|

|---|---|---|---|

| 300nm |  |

|

|

| 250nm |  |

|

|

| 200nm |  |

|

|

| 180nm |  |

|

|

| 170nm |  |

|

|

| 160nm |  |

|

|

| 150nm |  |

|

|

| 140nm |  |

|

|

| 130nm |  |

|

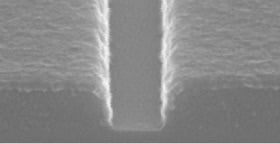

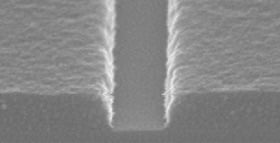

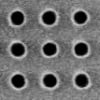

Thick Film KrF Resist

A positive resist that can ensure a film thickness of even 10μm, this product is used for thick film plating and staircase layer formation.

TDUR-P9001 CO

Profile

- Specifically designed resist for thick film patterning

- High resolution and vertical profile even in thick film

- ISO Trench Target CD Size: 1.5μm

Conditions

Substrate

Si with HMDS

Resist Thickness

9.2μm (RI: 1.56)

Pre-bake

140℃, 60sec

Exposure

KrF stepper (NA: 0.55, σ: 0.49)

Reticle

Binary Reticle

P.E.B

110℃, 60sec

Development

NMD-3 2.38%, 23℃, 60sec

Post-bake

100℃, 60sec

Target CD

Trench: 1.5μm space / 16.5μm pitch ; Dot: 1.5μm space / 12.0μm pitch

TDUR in the text is a pending or registered trademark of TOK.

Please Feel Free to Contact Us for More Information

For any questions or concerns,

Send an Inquiry Through the Web

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.