Black Resist

Resist with Environmental Characteristics in Addition to Uniformity and Fineness of the Formed Film

As part of the development of photolithography for display applications, we have been designing and developing photosensitive black pigment films. In addition to achieving uniformity and fineness, we have also obtained the environmental characteristics of a permanent formed film.

WTP BK Series

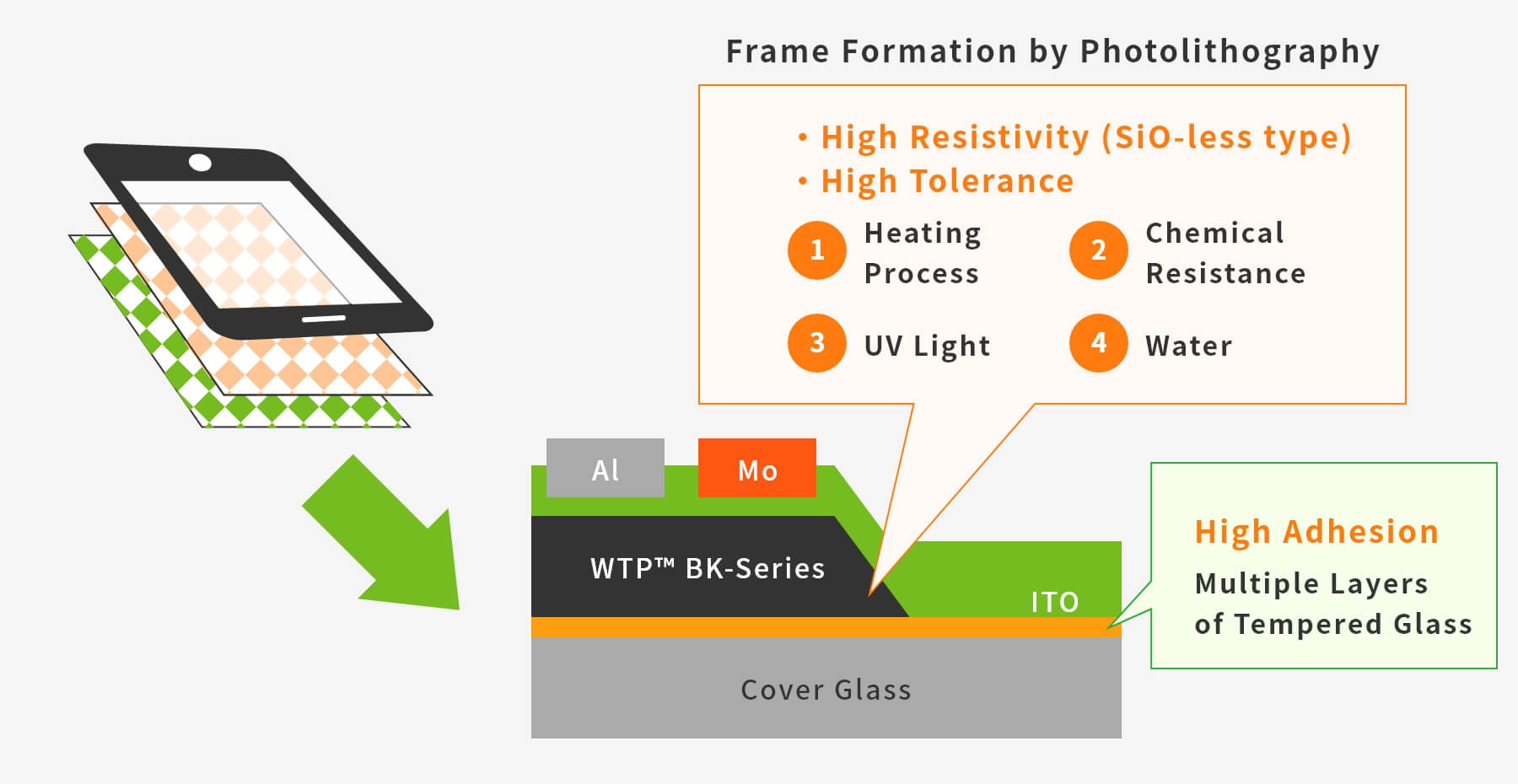

Black Resist for Frames

In addition to its function as a light-shielding film, this negative resist has multiple functions, including chemical resistance and high adhesion. This product is used for touch panel frames.

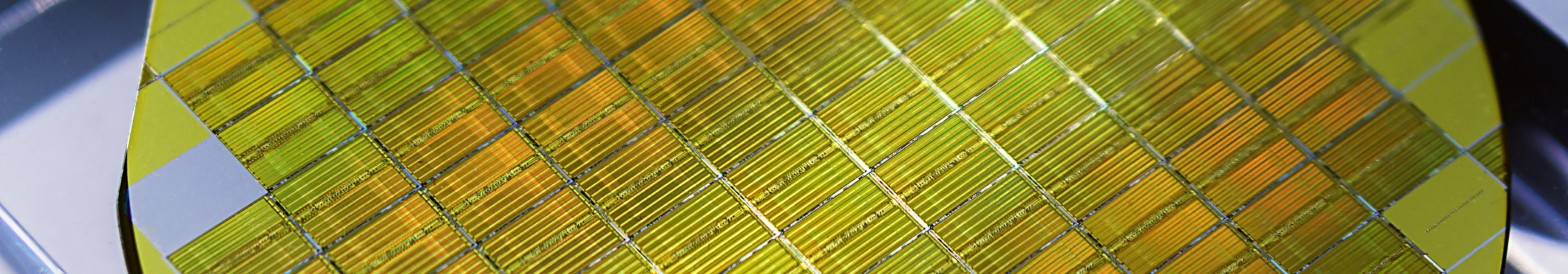

Touch Panel Image of Cover Glass

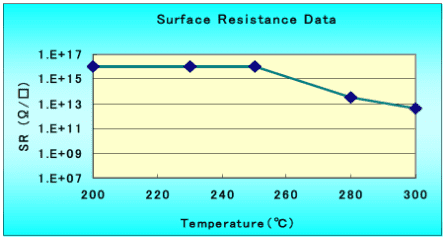

Surface Resistance

Conditions

Substrate

CS glass (with alkali treatment)

Pre-bake

100℃, 120sec / Direct Hot Plate

Film Thickness

1.5μm (after post-bake)

Exposure

Mirror Projection Aligner,

200mJ/cm2, 15mW (JK-cut),

Mask 200μm Gap

Post-bake

60min at each temperature

Shape

Conditions

Substrate

CS glass (with alkali treatment)

Pre-bake

100℃, 120sec / Direct Hot Plate

Film Thickness

1.5μm (after post-bake)

Exposure

Mirror Projection Aligner,

200mJ/cm2, 15mW (JK-cut),

Mask 200μm Gap 60min at each temperature

Development

KOH 0.04%, 25℃ for each time duration

Post-bake

240℃, 30min

10um Mask

| Development Time | |||

|---|---|---|---|

| 50sec | 60sec | 70sec | |

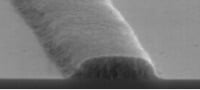

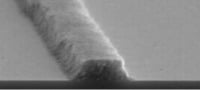

| WTP BK Series |  |

|

|

CFPR BK Series

Black Resist for Color Filter

This is a negative-type resist designed and developed to form a light-blocking barrier film for color filters using the photolithography process, which used to be formed by etching a chrome film. This resist has a black color, a light-blocking property with an optical density (OD) value of about 4, and high electrical resistance, and is used in the manufacture of color filters for displays.

Normal Type

| Material Characteristics | CFPR BK-6161SL |

|---|---|

| OD / 1 μm | 4.5 |

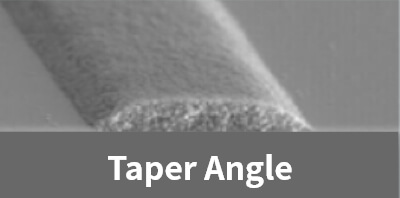

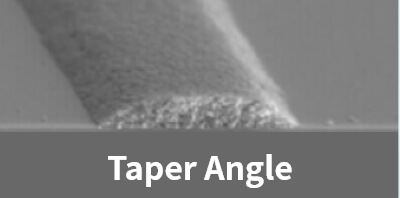

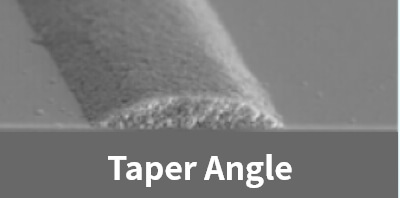

| BM Shape Angle | > 50° |

| Width | 5.0 μm |

| Surface Resistance | 10E15Ω |

| Concentration | 14.5% |

| CFPR BK-6161SL | ||

|---|---|---|

| 40mJ | 60mJ | |

| 50sec |  6.1 μm |

7.4 μm |

| 60sec |  5.4 μm |

6.5 μm |

| 70sec |  4.9 μm |

5.8 μm |

Conditions

Substrate

EXG glass

Pre-bake

100℃, 120sec / Direct Hot Plate

Film Thickness

1.0μm (after post-bake)

Exposure

Mirror Projection Aligner,

20mW, 200μm Gap,

40, 60mJ/cm2

Post bake

230℃, 30min

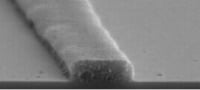

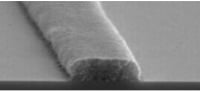

High Resistance Type

| Material Characteristics | CFPR BK-7742SL |

|---|---|

| OD / 1 μm | 4.0 |

| BM Shape Angle | > 70° |

| Width | 5.0 μm |

| Surface Resistance | 10E15Ω |

| Concentration | 14.5% |

Conditions

Substrate

EXG glass

Pre-bake

110℃, 90sec /

Proximity pin 0.5mm

Film thickness

1.3μm (after post-bake)

Exposure

Mirror Projection Aligner,

60, 80, 100mJ/cm2

Development

KOH 0.04% at 23℃

Post bake

230℃, 20min oven

| 60mJ | 80mJ | 100mJ | |

|---|---|---|---|

| 60sec |  5.5 μm |

6.0 μm |

6.2 μm |

| 70sec |  4.1 μm |

4.6 μm |

4.9 μm |

| 80sec |  3.3 μm |

3.9 μm |

4.1 μm |

CFPR in the text is a pending or registered trademark of TOK.

Please Feel Free to Contact Us for More Information

For any questions or concerns,

Send an Inquiry Through the Web

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.