G- and I-Line Resist

General Purpose G- and I-Line Resists for

Semiconductors and MEMS

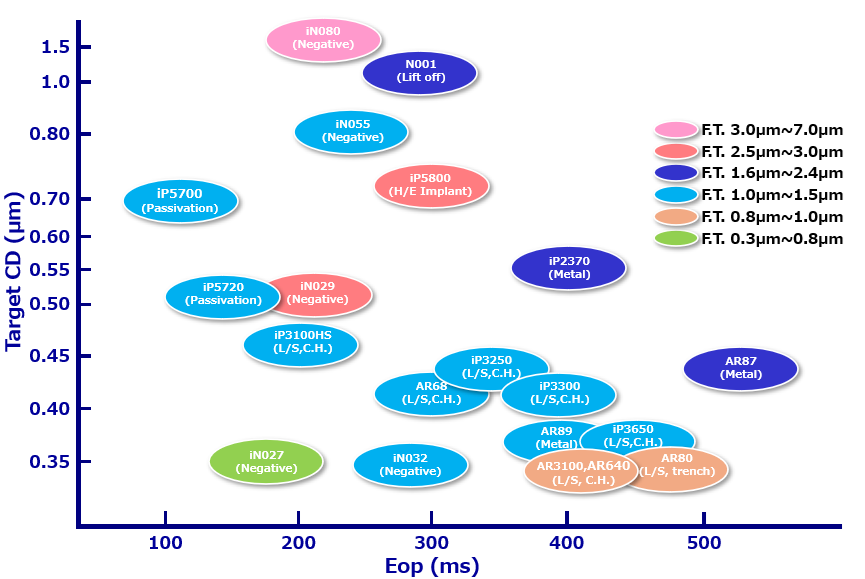

We offer both positive and negative resists for g-, h-, and i-line projection exposure with long wavelengths as well as for high NA g- and i-line stepper exposure systems. We offer a wide range of resists, including thick film types, high-sensitivity types, dye-infused types for high-reflection substrates such as polysilicon and tungsten wiring, etc. The following is a list of our representative products. Please feel free to contact us for regarding these or additional types of products.

G-Line Resist

Substrate

Bare-Si (HMDS coated)

Film thickness

1.26μm

Pre-bake

Pre-bake :90℃, 90sec

(110℃, 90sec /no post exposure bake)

Exposure

g-line stepper (NA: 0.54)

Post Exposure

Bake (P.E.B.)

110℃, 90sec

(alternatively, no P.E.B.)

Development

NMD-3 2.38%, 60sec

Post-bake

110℃, 90sec (proximity)

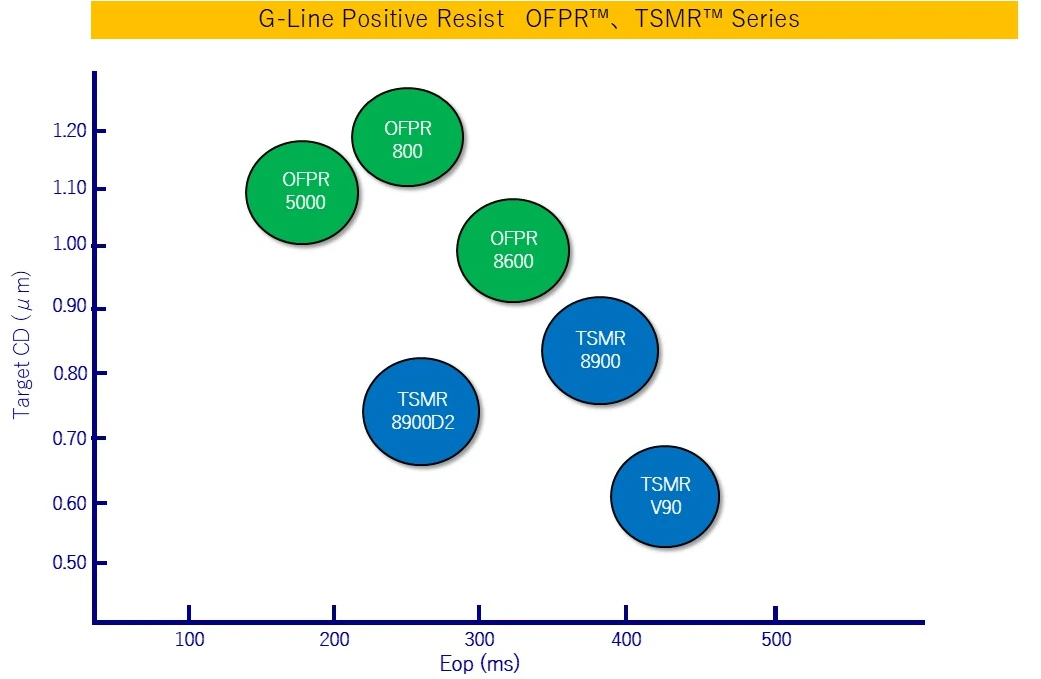

G-Line Positive Photoresist

OFPR™Series、TSMR™Series

These are positive photoresists with a photosensitive wavelength corresponding to the g-line (436nm).

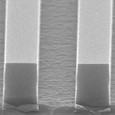

Depending on the series, high resolution target dimensions of down to 0.7μm are possible with minimal striation. Within the OFPR™ series, OFPR™-800 has been widely used as a g-line positive photoresist in combination with the organic alkaline developer OFPR™-NMD-3 2.38%. The TSMR™ series is characterized by high-resolution resists for use with higher NA steppers. We also offer a wide variety of products, including the TSMR-V series, which features a rectangular shape, and the dye-infused TSMR-CR, which is designed for use with high-reflection substrates.

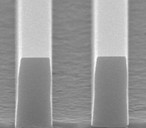

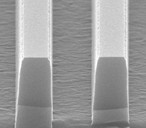

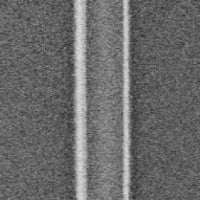

TSMR™-V90

Features

- Excellent resolution and overall fidelity of 0.45μm with NA 0.54 stepper

- Wide DOF tolerance to maintain good pattern quality

- Higher sensitivity and higher throughput

- Excellent dimension control due to reduced standing wave effects

Substrate

Si (HMDS)

Film thickness

1.25μm

Pre-bake

100℃, 60sec

Exposure

NSR-1505G7E

P.E.B

120℃, 90sec

Development

NMD-3 2.38%,

23℃, 60sec

Resolvability

| 0.4μm | 0.45μm | 0.5μm | 0.6μm | 0.7μm | 0.8μm | |

|---|---|---|---|---|---|---|

| TSMR-V90 Eth:270ms Eop:550ms (0.8μm) |

|

|

|

|

|

|

OFPR&TSMR in the text is a pending or registered trademark of TOK.

Please Feel Free to Contact Us for More Information

For any questions or concerns,

Send an Inquiry Through the Web

I-Line Resist

Substrate

Bare-Si (HMDS coated)

Film thickness

Refer Above

Pre-bake

90℃, 90sec (proximity)

Exposure

i-line stepper (NA: 0.57, σ: 0.56)

P.E.B.

110℃, 90sec

(alternatively, no P.E.B.)

Development

NMD-3 2.38%, 60sec

Post-bake

110℃, 90sec (proximity)

I-Line Positive Photoresist

TSMR™、THMR™-iP、TDMR™-AR Series

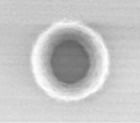

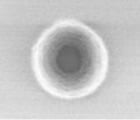

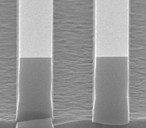

A photoresist with a photosensitive wavelength corresponding to the i-line (365nm). High resolutions of down to 0.35μm lines and 0.4μm holes can be achieved with minimal striation. It is also easy to develop with TMAH, has low metal impurities such as Na and Fe, and is easy to strip away.

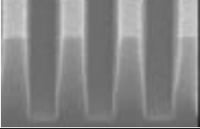

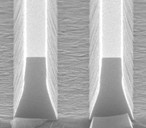

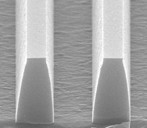

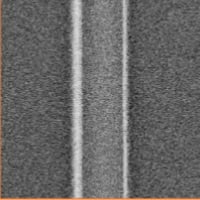

TDMR™-AR80

High-resolution i-line positive photoresist. Excellent for fine pattern formation.

Substrate

Si (HMDS)

Film thickness

0.84μm

Pre-bake

90℃, 90sec

Exposure

i-line stepper (NA: 0.57)

P.E.B

110℃, 90sec

Development

NMD-3 2.38%, 23℃, 60sec

Resolvability

Eth:190ms Eop:465ms

| 0.28μm | 0.30μm | 0.35μm | 0.40μm |

|---|---|---|---|

|

|

|

|

DOF Performance

0.35μmL/S Eth:220ms Eop:540ms Film Thickness 1.05μm

| 0 |

|---|

|

| 0.2 | 0.4 | 0.6 | 0.8 | 1.0 |

|---|---|---|---|---|

|

|

|

|

|

| -0.2 | -0.4 | -0.6 | -0.8 | -1.0 |

|

|

|

|

DOF Performance

0.40μmC/H Eth:167ms Eop:779ms Film Thickness 0.84μm

| 0 |

|---|

|

| 0.2 | 0.4 | 0.6 | 0.8 | 1.0 |

|---|---|---|---|---|

|

|

|

|

|

| -0.2 | -0.4 | -0.6 | -0.8 | -1.0 |

|

|

|

|

|

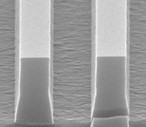

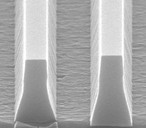

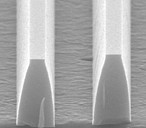

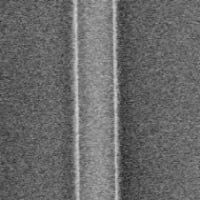

TSMR™-CR57i10

The dye content prevents halation caused by reflected light on Al and other high-reflection substrates,

enabling patterning.

Substrate

AI-Si

Film thickness

3.5μm

Pre-bake

90℃, 60sec

Exposure

i-line stepper (NA:0.50 σ:0.60)

P.E.B.

120℃, 60sec

Development

NMD-3 2.38%, 23℃, 65sec

Post-bake

100℃, 60sec

Resolvability

Eop 1.5μL/S

| 0.8μm | 0.9μm | 1.0μm | 2.0μm | 3.0μm | 5.0μm |

|---|---|---|---|---|---|

|

|

|

|

|

|

DOF Performance

Eop 1.55μm L/S 350ms Film Thickness 2.1μm

| 0.0μm |

|---|

|

| -0.3μm | -0.6μm | -0.9μm | -1.2μm | -1.5μm | -1.8μm | -2.1μm | 2.4μm |

|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

| +0.3μm | +0.6μm | +0.9μm | +1.2μm | +1.5μm | +1.8μm | +2.1μm | +2.4μm |

|

|

|

|

|

|

|

|

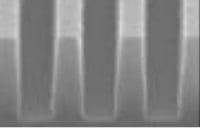

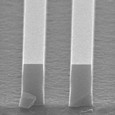

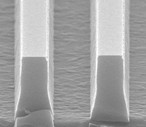

I-Line Negative Photoresist

TSMR-iN Series

This is a negative photoresist with a photosensitive wavelength corresponding to the i-line (365nm). It has high heat resistance and high wet/dry etching resistance.

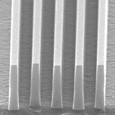

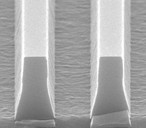

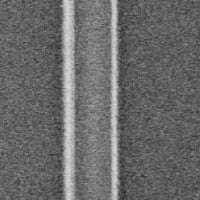

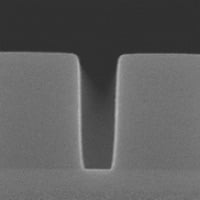

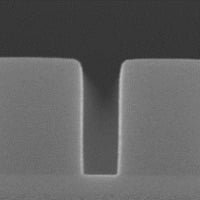

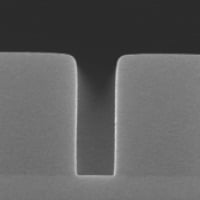

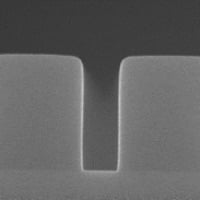

TSMR™-iN080

It is excellent for covering stepped substrates with thicker films and while reducing developer residue.

Resolvability

Substrate

Si (HMDS)

Film thickness

3μm

Pre-bake

90℃, 120sec

Exposure

i-line stepper (NA: 0.57)

P.E.B.

110℃, 60sec

Development

NMD-3 2.38%, 23℃, 60sec

Post-bake

100℃, 60sec

700nm

| -0.6 | -0.3 | 0 | 0.3 |

|---|---|---|---|

|

|

|

|

|

|

|

|

DOF Performance

Substrate

Si (HMDS)

Film thickness

5.8μm

Pre-bake

90℃, 120sec

Exposure

g-line stepper (NA: 0.54)

P.E.B.

110℃, 60sec

Development

NMD-3 2.38%, 120sec

5μm Space

| 0 |

|---|

|

| 1.0 | 1.5 | 2.5 | 3.0 | 3.5 |

|---|---|---|---|---|

|

|

|

|

|

| -1.0 | -1.5 | -2.5 | -3.0 | -3.5 |

|

|

|

|

|

Heat Resistance

Film Thickness: 5.8μm, Post-bake Time: 300sec

| none |

|---|

|

| 140℃ | 150℃ | 160℃ | 200℃ | 250℃ | 300℃ |

|---|---|---|---|---|---|

|

|

|

|

|

|

TSMR, THMR and TDMR in the text are pending or registered trademarks of TOK.

Please Feel Free to Contact Us for More Information

For any questions or concerns,

Send an Inquiry Through the Web

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.