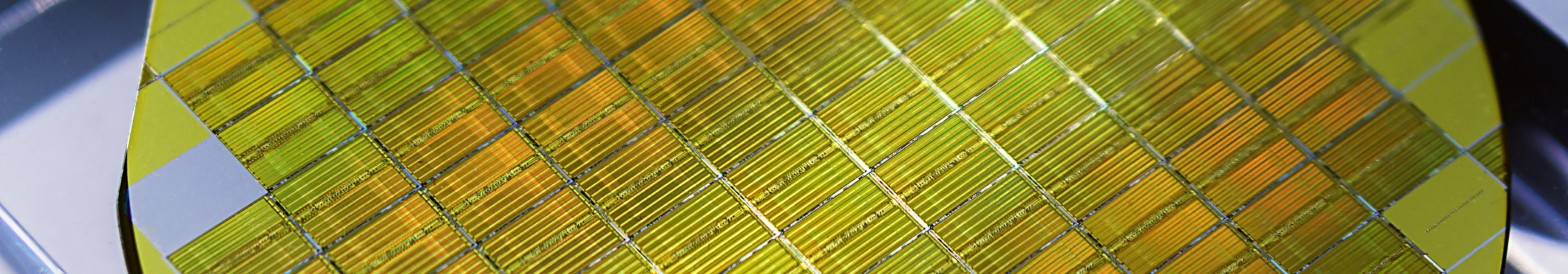

Redistribution Layer (RDL) Resist

Photoresist for Redistribution Layer (RDL) Plating

We offer a wide range of resists for rewiring and plating from thin to thick films of 2~20µm. We provide the latest in high-density semiconductor packaging technology with our resists characterized by high resolution and DOF margin, including applications in 2.5D/3D semiconductor packaging, TSV-Si through-electrode stacked memory, WL-CSP (Wafer Level Chip Size Package), FOWLP/FOPLP (Fan Out Wafer-/Panel-Level Package), and forming fine RDLs on silicon interposers. We offer both naphthoquinone-type resists with excellent resistance to mounting environments and chemical amplification type resists with high resolution. We also offer products that can be used in a variety of processes, including a high-resolution type that can be used with Na2CO3 inorganic alkaline developer.

TMMR P-W1000T

This product is an NQD-based photoresist for forming high-resolution RDLs, which can be used in NQD-based processes without being affected by the environment.

Features

- Positive type

- Developer:NMD-3 2.38% (TMAH 2.38%)

- Resist film thickness: 4〜12μm

- High resolution, rectangular profile, good peelability

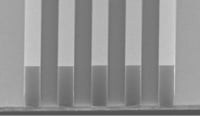

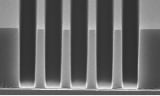

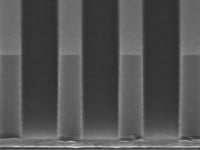

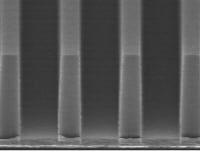

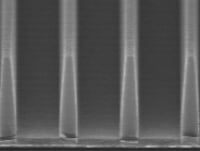

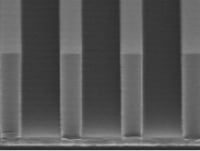

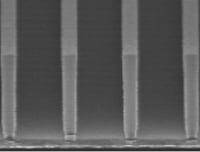

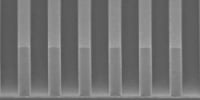

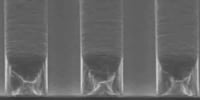

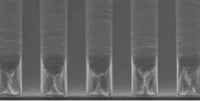

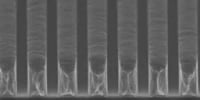

Lithography Image

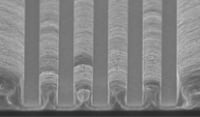

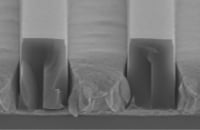

| Resist Pattern Shape | After Cu Plating | After Resist Removal | |

|---|---|---|---|

| Resist Thickness 5μm L/S : 2μm / 2μm |

|

|

|

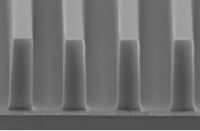

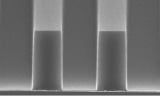

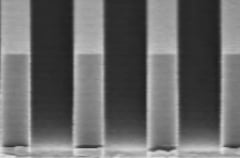

| Resist Thickness 8μm L/S : 3μm / 3μm |

|

|

|

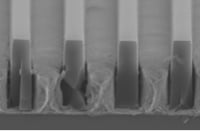

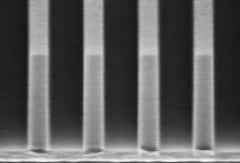

| Resist Thickness 8μm L/S : 6μm / 6μm |

|

|

Conditions

Substrate

Cu

P.A.B.

110℃, 90sec

Exposure

i-line stepper

Development

NMD-3 2.38% (TMAH 2.38%),

60sec x 2 paddles

Stripping

ST104 70℃, 600sec

TMMR in the text is a pending or registered trademark of TOK.

PMER P-BZ Series

This is a photoresist for RDL formation for thick films of 8~20μm. A rectangular shape can be obtained even in thick film areas.

Features

- Positive type

- Developer:NMD-3 2.38% (TMAH 2.38%)

- Resist film thickness: 8〜20μm

- Wide process margin, good peelability

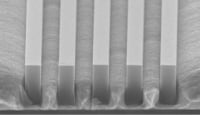

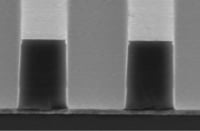

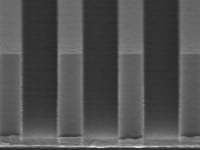

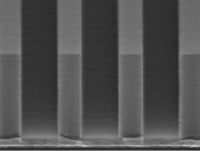

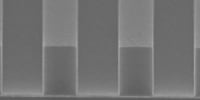

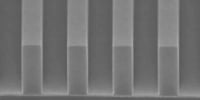

Resist Pattern Shape

| Line/Space | 10μm/10μm | 8μm/8μm | 6μm/6μm | 4μm/4μm |

|---|---|---|---|---|

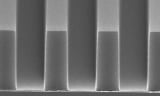

| Resist Thickness 20μm |

|

|

|

|

Conditions

Substrate

Cu

P.A.B.

140℃, 330sec

Exposure

g-, h-, i-line stepper (NA: 0.18)

P.E.B.

100℃, 180sec

Development

TMAH 2.38%, 60sec x 2 paddles

PMER P-CM Series

This series of photoresist for ultra-high resolution RDL formation, which is used to form 1.5μm patterns, has an extremely wide defocus margin and good plating solution resistance.

Features

- Positive type

- Developer:NMD-3 2.38% (TMAH 2.38%)

- Resist film thickness:3〜12μm

- Wide DOF margin, good peelability

Resist Profile

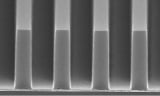

| Line/Space | 2μm/2μm | 1.5μm/1.5μm |

|---|---|---|

| Resist Thickness 6μm |  |

|

DOF Margin

| Resist Thickness 6μm Center  = 2.5μm L/S |

+4μm | +8μm | +12μm |

|---|---|---|---|

|

|

|

|

| -4μm | -8μm | -12μm | |

|

|

|

Conditions

Substrate

Cu

P.A.B.

130℃, 300sec

Exposure

i-line stepper (NA: 0.18)

P.E.B.

100℃, 90sec

Development

NMD-3 2.38% (TMAH 2.38%),

30sec x 2 paddles

PMER P-CP50

Slit coater coating is also possible, with this high-resolution resist for RDL formation that is suitable for the panel-level packaging process of large substrates and has excellent characteristics for h-line specialized exposure systems.

Features

- Positive type

- Resist suitable for h-line exposure systems

- Developer:NMD-3 2.38% (TMAH 2.38%)

- Resist film thickness:3~8μm (slit coater)

- Wide DOF margin, good peelability

| Line/Space Resist Thickness 7μm |

5μm/5μm | 3μm/3μm | 2μm/2μm |

|---|---|---|---|

| After Development |  |

|

|

| RDL Formation After Resist Removal |

|

|

|

Conditions

Substrate:

Cu

P.A.B.

130℃, 240sec

Exposure

h-line direct write exposure system, 600mJ/cm2

P.E.B.

90℃, 240sec

Development

NMD-3 2.38% (TMAH 2.38%),

60sec x 2 paddles

PMER in the text is a pending or registered trademark of TOK.

Please Feel Free to Contact Us for More Information

For any questions or concerns,

Send an Inquiry Through the Web

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.