Displays

Tokyo Ohka Kogyo technologies and products contribute to the manufacturing of displays and panels for devices that have become a part of our daily lives, such as smartphones, tablet PCs, and flat-screen TVs. In recent years, panel production has been in constant demand for innovations in reduced weight, thinner profile, and higher image quality. In addition, research and development of cutting-edge technologies such as “wearable displays” and “flexible displays” is progressing at a rapid pace. The synergy between our materials technology and coating technology, which boasts high uniformity as well as high precision, enables us to achieve both higher resolution and more economical displays.

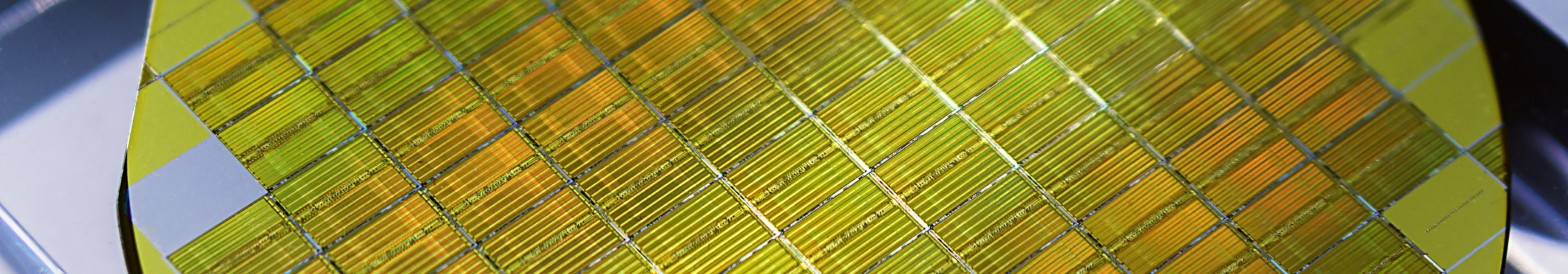

Main Manufacturing Processes for Liquid Crystal Displays (LCDs)

Array Processes

Process Film Deposition

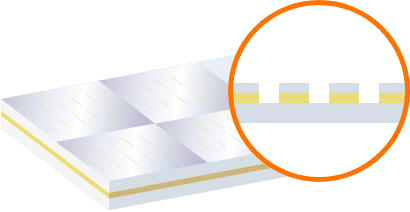

The Thin Film Transistor (TFT) is a thin, uniform layer of material that is deposited on a large surface area glass substrate. The process is carried out using sputtering equipment for the metal film and CVD equipment for the insulating and semiconductor films.

Process Photolithography

Photoresist, a material that reacts to light, is quickly and evenly applied to the entire glass substrate. The next step is to use an exposure device to apply light and copy the TFT pattern formed on the mask according to the designed circuit. During the development process, the photoresist in the exposed area is dissolved by the developing solution, leaving only the TFT pattern intact.

We provide high-definition photoresists for TFTs and transparent materials with high reliability.

Related Products

Process Etching/Resist Stripping

Parts of the pattern not covered by resist are removed to form the circuit. After etching, the photoresist is no longer needed and is removed. We offer a wide range of high purity thinners and stripping solutions.

Related Products

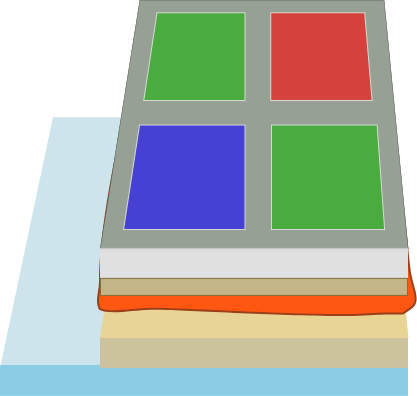

Process Liquid Crystal Filling/Assembly

Liquid crystal material is deposited between the TFT substrate and the color filter substrate, and they are bonded together.

The polarizer and backlight are then bonded together to complete the liquid crystal display.

Organic EL Displays

We provide photoresists for Organic Light Emitting Diode (OLED) displays,

which are expected to be the mainstay of next-generation displays.

Touch Panels

In addition to insulating materials suitable for the manufacture of touch panels, we also develop and supply UV curing systems that can satisfy both heat resistance and dry-etch resistance as well as releasability.

OLED Display Related Products

Related Information

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.