Material Q&A

The following is a list of questions we often receive from our customers regarding the materials we provide, in Q&A format.

If you have any questions that are not listed here, please contact us using the inquiry form.

We will have a specialist reach out to you.

Questions About Processes

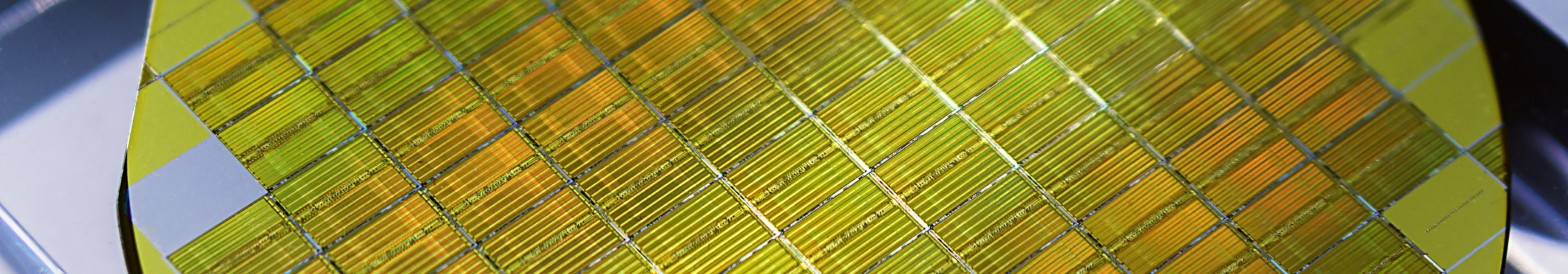

- What is lithography?

- The word lithography comes from the Greek word lithos, meaning stone, and graphia, meaning to write. Lithography is the process of creating patterns on a silicon wafer using a photosensitive resin solution called photoresist.

- What is microfabrication?

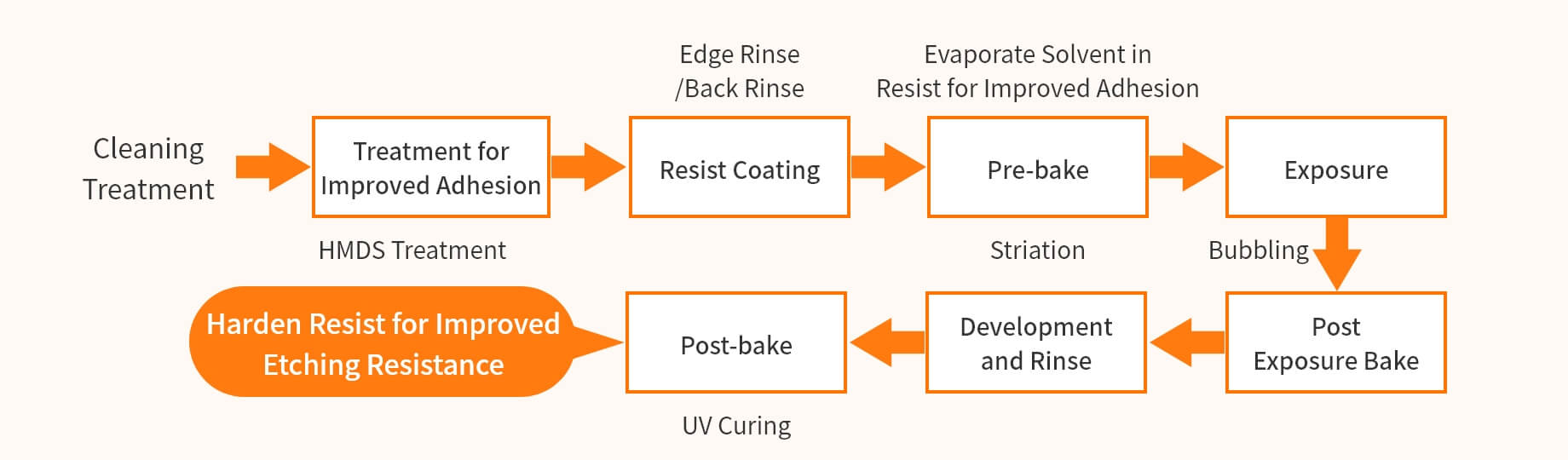

- Processing semiconductors involves a repetitive process of thin film formation, microprocessing, and impurity introduction.

The microfabrication process in photolithography involves the exposure and development of a photoresist, and the remaining resist protects the substrate during etching and impurity introduction.

- What does pretreatment involve?

- Pretreatment processing includes cleaning, dehydration baking and HMDS treatment to eliminate foreign particles.

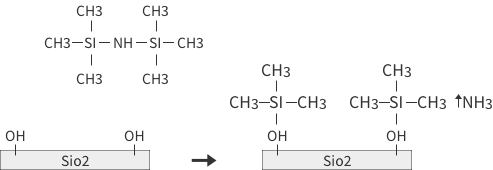

- What is HDMS treatment?

-

The surface of the wafer is hydrophilic and does not adhere well to photoresist, so HMDS treatment improves adhesion by making it hydrophobic.

- What is striation?

- Striation is unevenness in the applied photoresist, where the surface is not smooth and has bumpy or radiating edges. Since the organic solvent of the resist dries quickly, unevenness in evaporation during the rotary coating process will cause this to phenomenon.

- What is PCD and PED?

- PCD (Post Coating Delay) and PED (Post Exposure Delay) are used to describe the time between coating or exposure, respectively, and the next processes. A consistent time between processes is necessary, otherwise variations in time could lead to changes in dimensions, poor development, etc.

- What is edge rinsing and back rinsing?

-

A thinner is used to remove resist that has been applied by the coater to the edges and backside of the wafer, which can attract dust.

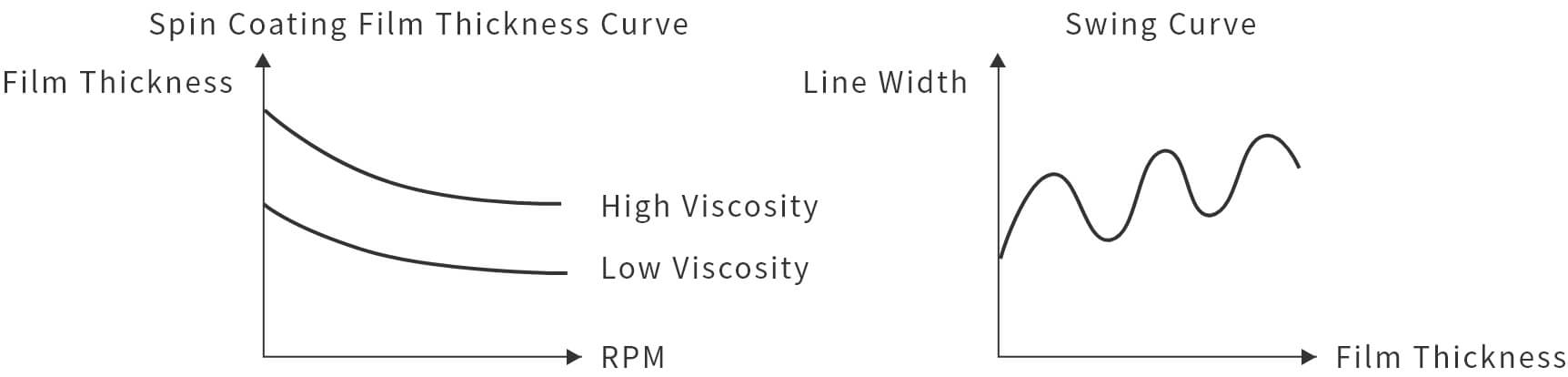

- What is a swing curve?

- The thickness of the coated resist is inversely proportional to the rpm squared, which in turn is proportional to the viscosity. After exposure and development, the line width will have a swing curve due to factors such as the amount of exposure, reflectivity of the substrate, and standing waves.

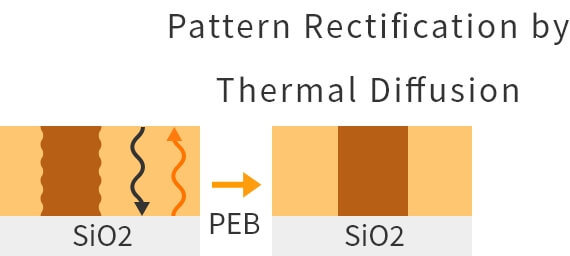

- What are the effects of P.E.B.?

-

P.E.B. (Post Exposure Bake) refers to the baking process of the wafer after exposure. One of the effects of P.E.B. is that the standing waves generated inside the resist by incoming light and the reflected waves from the substrate cause the resist to develop a corrugated surface, but the thermal energy causes the reaction to equalize, resulting in the formation of a curved line. However, the uniformity of the reaction caused by the thermal energy will improve the flatness of the resist pattern.

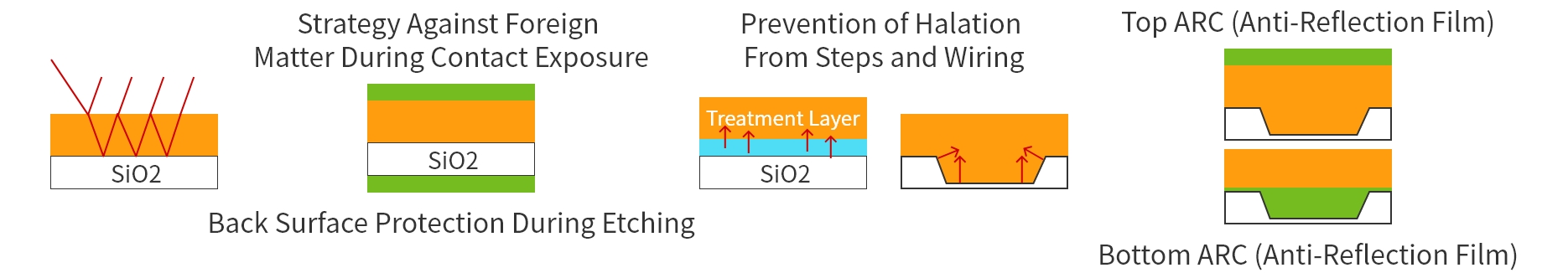

- Is there a treatment for reflections from the substrate?

- To prevent substrate reflection, a surface reflection-preventing film is used, and a dye is added to prevent reflection in the resist solution.

- What is UV curing?

- UV curing is a process to improve heat resistance by polymerizing resin in the resist (curing) through irradiating with ultraviolet (UV) light.

- What causes bubbling?

- Bubbling occurs when N₂ gas from decomposition of the photosensitive material in the resist does not escape through the resist film. The process can be reduced by shortening the HMDS processing time, reducing the resist film thickness, and increasing the pre-bake temperature.

- What causes scumming and what are some treatment plans?

- Scumming can occur for a variety of reasons. The main reasons are residue of the exposed area in the developing solution, the re-deposition of dissolved material in the developing solution, and adhesion to the substrate. In order to reduce scumming, it is necessary to take appropriate measures.

Questions About Products and Warranty

- What are QT bottles, GA bottles, and canisters?

- Traditionally, photoresist is packaged in brown glass QT (quart) bottles and GA (gallon) bottles. These are 0.946 liters and 3.785 liters respectively. A canister is a stainless steel linked container with a capacity of 18 liters.

- What is SDS?

- SDS (Safe Data Sheet) is a sheet that contains data and information about the hazardous and toxic properties of chemical substances, etc. The purpose of SDS is to prevent occupational accidents, etc. by ensuring that handlers understand the hazardous and toxic properties of products in advance and carry out appropriate use and handling.

- What is the warranty period, temperature, delivery date, etc.?

- When using products, please refer to the latest SDS and the label, and take the utmost care when handling. Since the warranty period for resists is after production, they are typically made to order. Please allow at least 4 weeks for delivery, and place orders well in advance.

- What is HDMS treatment?

- The surface of the wafer is hydrophilic and does not adhere well to photoresist, so HMDS treatment improves adhesion by making it hydrophobic.

- Can resist be used immediately after removal from cold storage?

- Depending on the temperature of cold storage and the size of the bottle, it may take several hours to return to room temperature. If the temperature of the resist and developer is not kept at a constant level, it may cause sensitivity fluctuations.

- How necessary is it to clean the coater lines?

- Line cleaning is carried out during setup of a new coater, but after that, regular cleaning is necessary every 2~3 months to prevent of foreign substances.

Product List

You can search our products by application or by product category.

This section provides an overview of each of our semiconductor, display and sensor manufacturing processes and the products involved in each.

Our products include photoresists, structural and functional materials, high purity chemicals, and processing equipment.

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.