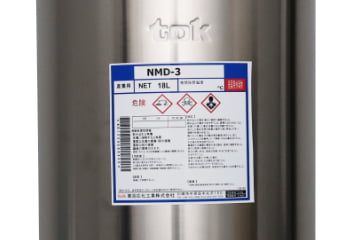

Developer and Rinse Solutions

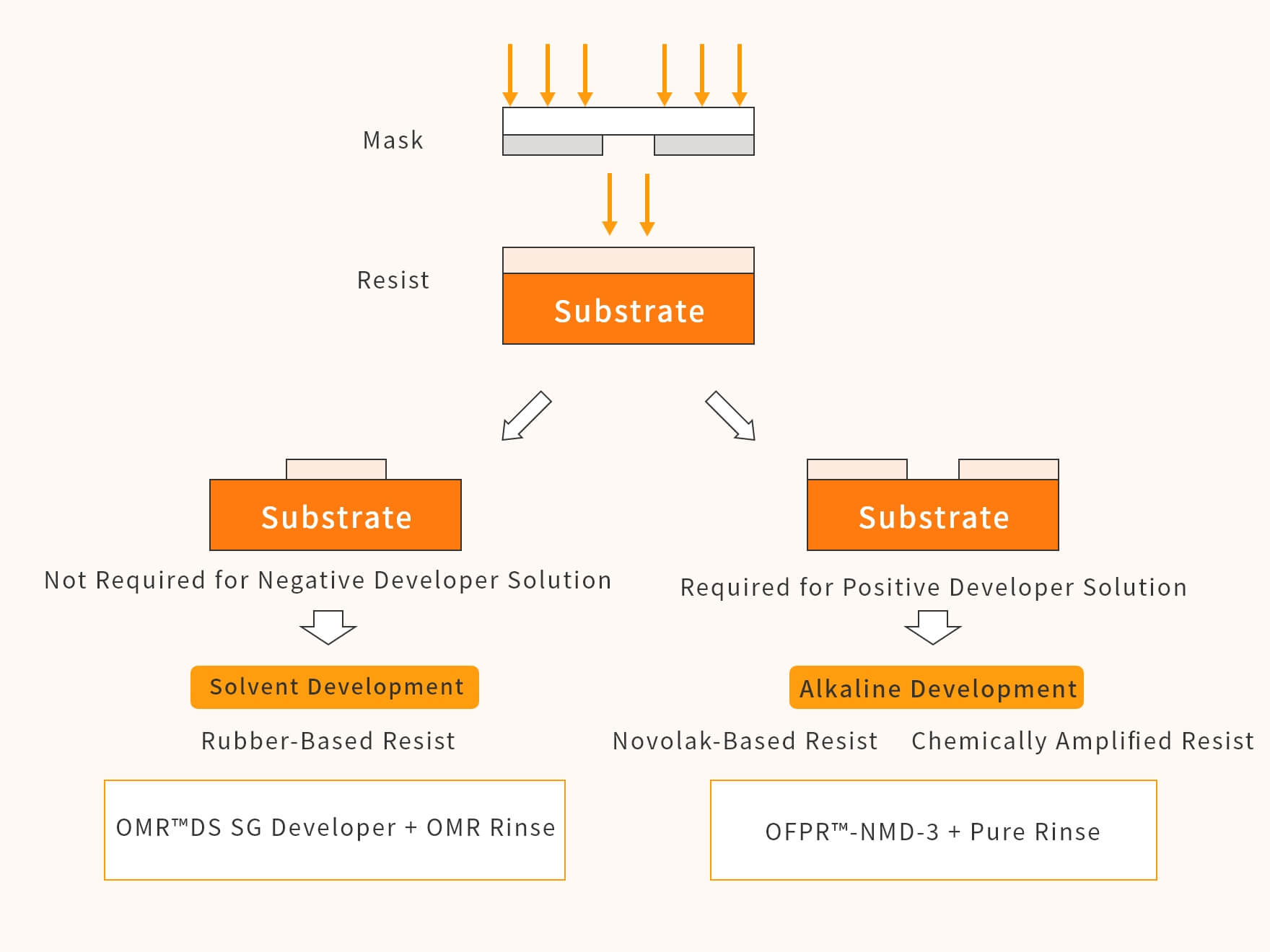

In most cases, organic solvents are used as developers for the negative type where the exposed area remains. Since the resist component is swollen by the organic solvent, a rinse solution of the same solvent is necessary after development. Alkaline developer is used in the case of the positive type where the unexposed area remains. TMAH (tetramethylammonium hydroxide) is usually used as an alkaline developer. Since it is an organic alkaline developer that does not contain metal ions, it can be used in semiconductor processes. The concentration is generally 2.38%, but we can provide various concentrations depending on the process used. Pure water is used as the rinse solution.

Purpose for Using Developer Solution

OMR Developer Series

Rubber-Based Negative Photoresist

Developer and Rinse

This is an exclusive developer for OMR negative resists, used in spray or in dipping processes. OMR developer tends to be slower in dissolving and better in resolving, so it is important to choose the right solution for each application. The purpose of the OMR rinse is to shrink the resist swollen by development and to clean the substrate.

OFPR Developer Series

Inorganic Alkaline Developer for Positive

Photoresist

As an inorganic alkaline developer, it is not recommended for use in semiconductor processing due to the potential for contamination with metal impurities. The OFPR developer series can be used for spray, dipping and paddle development. OFPR developer 3 is undiluted and should be diluted 2:1 or 1:1 with DI water. OFPR developer 4 and 5 are pre-diluted types.

Organic Alkaline Developer

Organic Alkaline Developer for Photoresist

(Metal Free)

- Good wettability (low surface tension)

- Minimal variation in dimensions within the wafer

- Little dependence of exposure on developer temperature

- De-aerating properties

OMR and OFPR in the text are pending or registered trademarks of TOK.

Please Feel Free to Contact Us for More Information

For any questions or concerns,

Send an Inquiry Through the Web

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.