Stripping Solution

Originally developed for the removal (stripping) of rubber-based negative resists, the use of positive resists has led to the development of strippers for both negative and positive resists.

Furthermore, in consideration of the environment, we have realized the elimination of chlorinated solvents and the implementation of non-phenol, and offer a variety of stripping solutions for each resist.

We have also commercialized stripping solutions that specialize in removing deposited or altered membranes after ashing or dry etching, and stripper solutions that take into account metal damage on devices.

Purpose for Using Stripping Solution

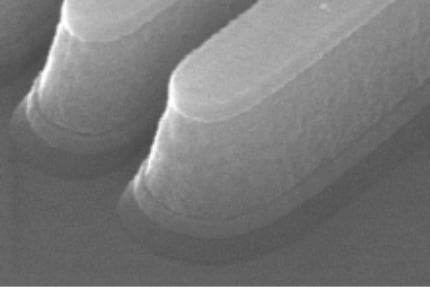

Removes Unnecessary Resist After Etching the Bottom Layer

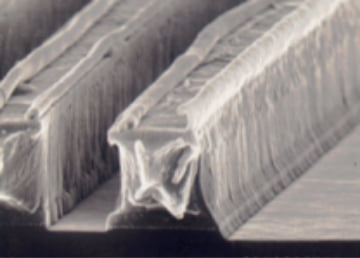

Removes Deposited (Unwanted) Material Generated During Etching

Stripping Solution for Both Negative and Positive Types

Stripping Solution 502A

Stripping solution 502A is a stripper for negative and positive photoresists that does not contain chlorinated solvents, which have become a problem in recent years due to environmental pollution. We have also commercialized Clean Strip HP-2, which does not contain phenol.

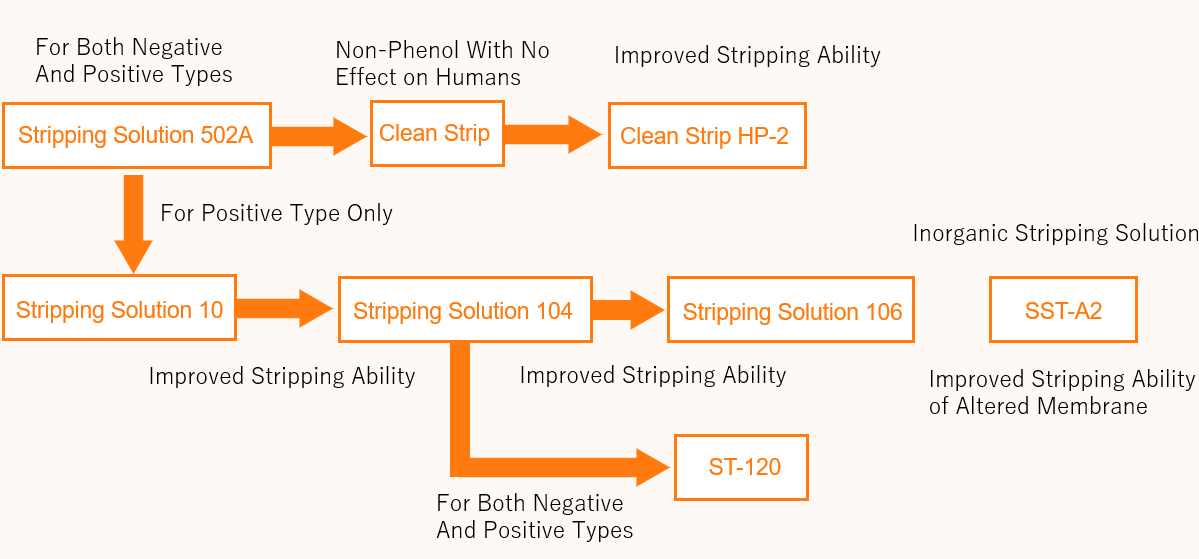

Relationship Between Stripping Solutions

Stripping Solution for Deposited Materials

Stripping Solution for Deposited Materials SST-A2

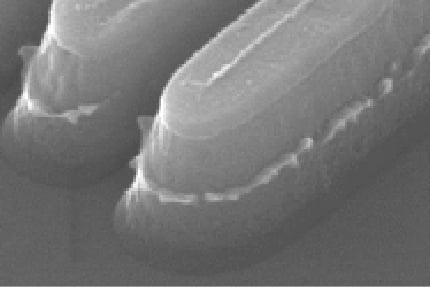

As patterns become smaller and finer, it becomes more difficult to remove deposited materials after dry etching, and a more powerful stripping solution is required.

SST-A2 is a water-soluble stripping solution for deposited materials after dry etching of Al-Si, Tin/Al-Si-Cu/TiN, Al-Si-Cu/TiN, Al-Si-Cu/TiN interconnects, SiO2/TiN/Al-Si-Cu, and SiO2/TiN/Al-Si holes at room temperature in a short time without damage to the metal.

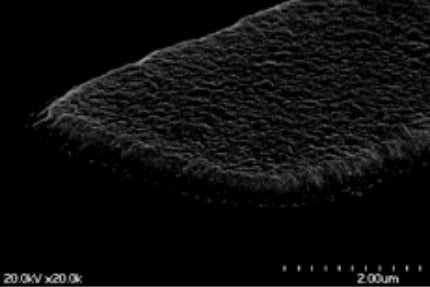

SST-A2 Stripping Ability

Residuals such as deposited materials are removed by low temperature treatment (23℃, 20min).

Stripping Solution for Deposited Materials

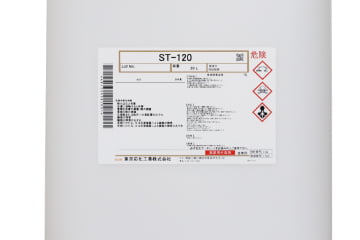

ST-120

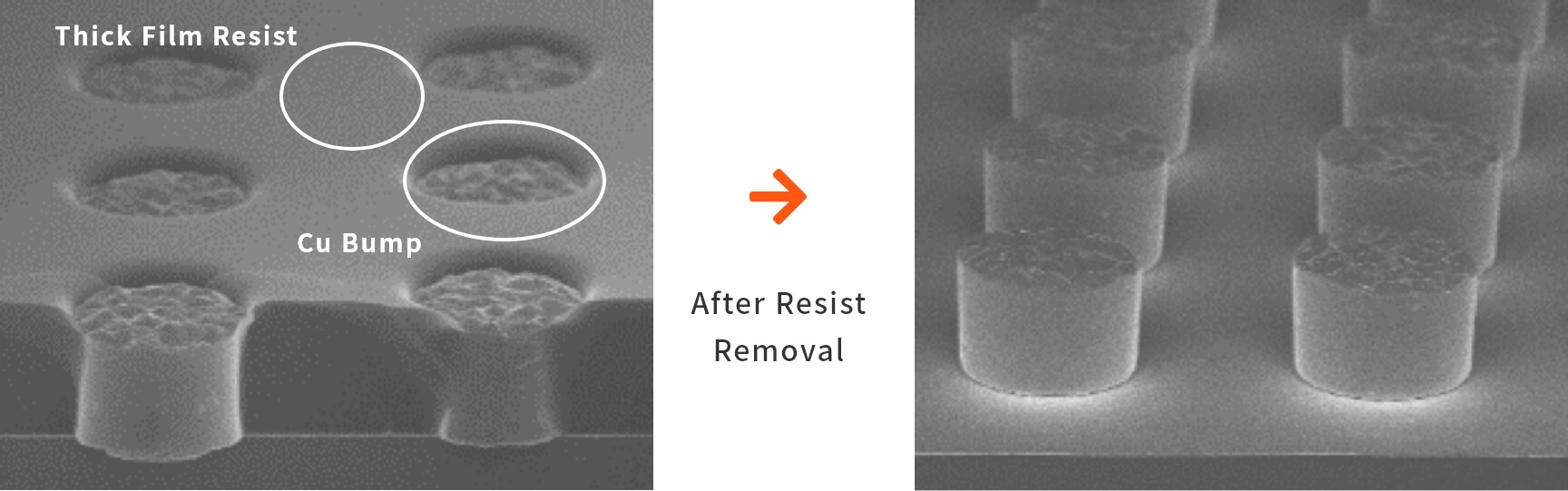

ST-120 is a stripping solution for thick film resists. It allows for water rinsing and low metal damage.

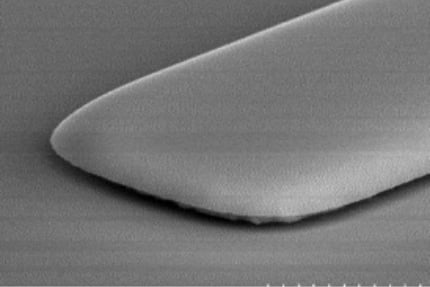

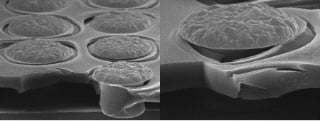

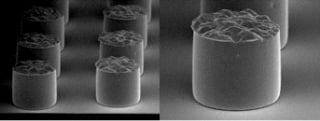

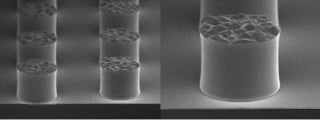

This is a SEM photo of ST-120.

ST-120 Stripping Ability

| Positive Resist | Negative Resist | |

|---|---|---|

| Initial Stage |  |

|

| Stripper 104 60℃, 20min × |

|

|

| ST-120 40℃, 10min 〇 |

|

|

Please Feel Free to Contact Us for More Information

For any questions or concerns,

Send an Inquiry Through the Web

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.