Protective Coating Materials

Protecting the Device Surface and Backside During Development, Etching and Dicing

Protective film material is resin material used to protect the surface of the device or the back of the device during development, etching or dicing.

The main resin solutions are OBC, which has the same resin component as negative resist, and OFR-5, which has the same resin component as positive resist. As a water-soluble resin, TPF is used for general purpose applications and TLDP-300 for protective coatings in laser processing.

OFR-5/OBC

Non-Photosensitive Resin Solution

Protects surfaces from contamination and damage caused by chemicals, damage, and foreign substances after coating and baking.

Two types of products are available: OFR-5, a novolac resin type that can be easily peeled off with alkaline water solution, and OBC, a rubber resin type with excellent chemical resistance to both acidic and alkaline conditions that can be peeled off with organic solvents such as xylene solvent.

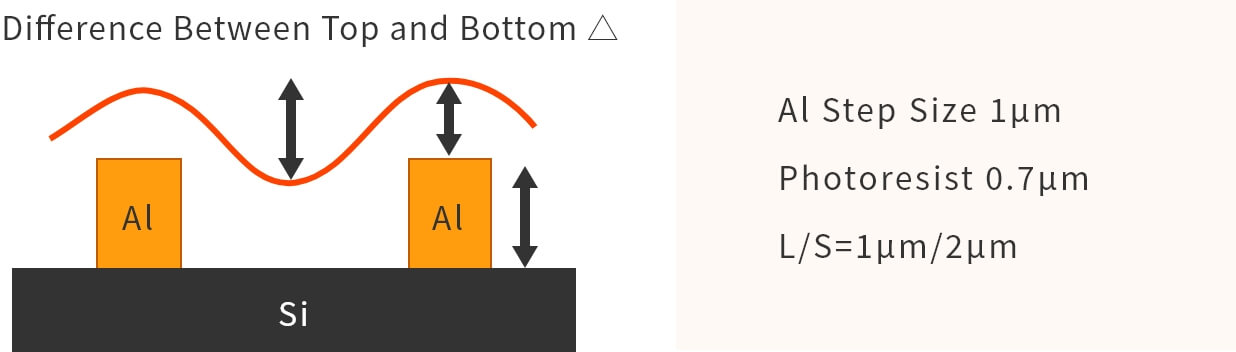

Regarding Flatness

| OFR-5 | OFPR-800 | |||

|---|---|---|---|---|

| 90℃ 90sec | 0.565μm |  |

0.664μm |  |

| 90℃ 90sec | 0.544μm | 0.690μm | ||

| 90℃ 90sec | 0.228μm | 0.693μm | ||

TLDP-300

Water Soluble Resin Solution

This solution is used to protect the surface of the wafer during laser processing.

Effect of TLDP™-300

| 3 Repetitions | 5 Repetitions | 9 Repetitions | |

|---|---|---|---|

| After Laser Irradiation |  |

|

|

| After Cleaning |  |

|

|

TLDP in the text is a pending or registered trademark of TOK.

Please Feel Free to Contact Us for More Information

For any questions or concerns,

Send an Inquiry Through the Web

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.