Adhesion Enhancing Materials

Surface Treatment Agent That Modifies Hydrophilic to Hydrophobic Properties and Adhesion Improver That Prevents Peeling Between Organic Film Layers

This is a surface treatment agent for ensuring adhesion to the substrate during the photolithography process and the formation of organic film laminated structures. We offer three types of products: a surface modifier that modifies the substrate surface to be hydrophobic, and two types of coating materials that improves the adhesion between the upper and lower layers when forming multilayer organic structures.

Product Description

OAP

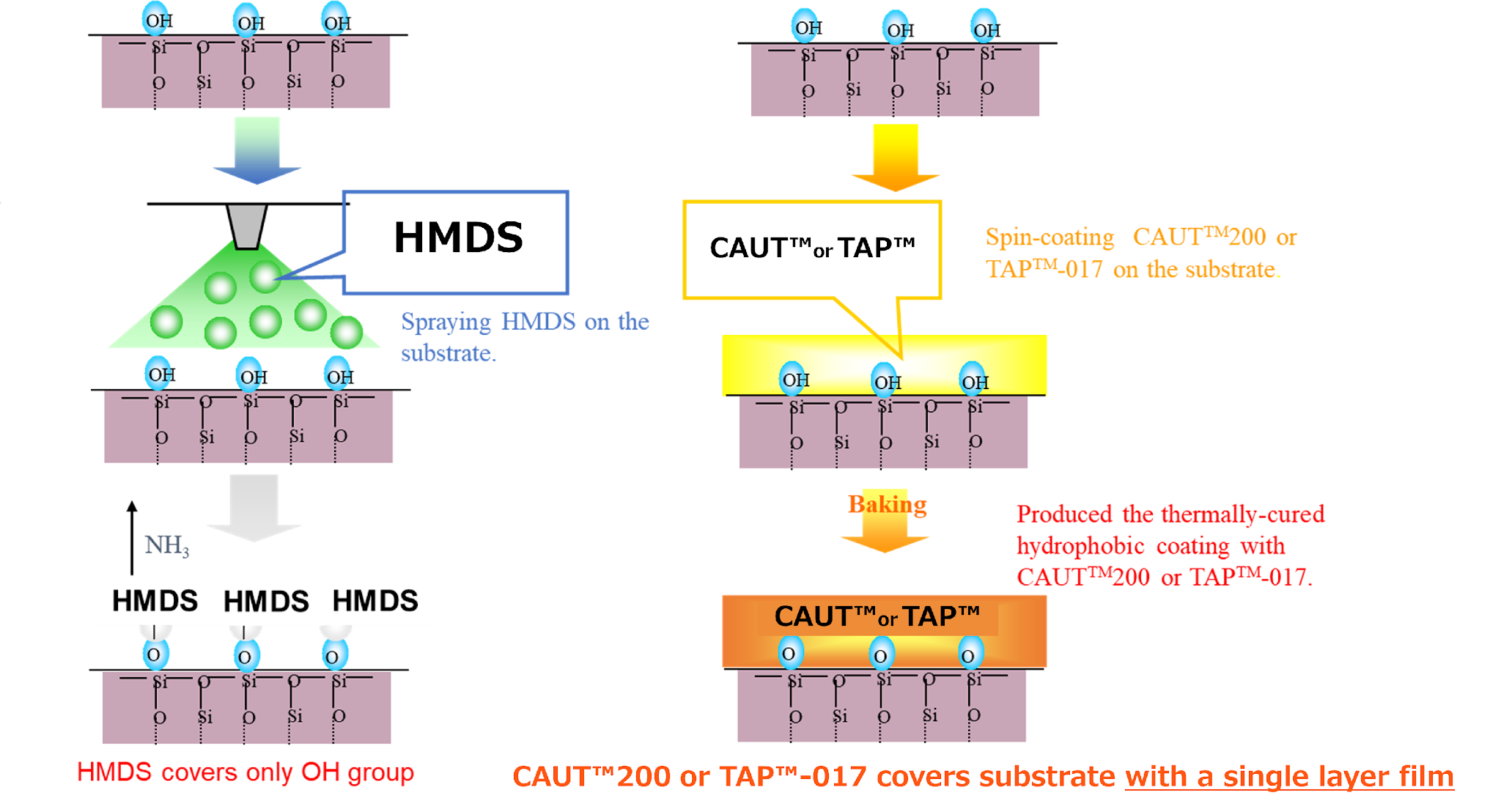

OAP (HMDS) treatment of substrates with hydrophilic (-OH) groups allows for a simple hydrophobic treatment with silylation.

It can be used in photolithography to improve the adhesion between the substrate and the photoresist.

CAUT-200、TAP-017

CAUT-200/ TAP-017 is a coating material that improves the adhesion between the base and top layers when forming multilayer structures.

By applying and baking CAUT-200 as a pretreatment for the top layer material on the base layer film (or substrate), CAUT-200 will form an organic layer of several nm on the surface of the base layer and improve the adhesion between the base layer film (substrate) and the top layer material.

Material Comparison Table

| OAP | CAUT200 | TAP-017 | ||

|---|---|---|---|---|

| Features |

|

|

|

|

| Adhesion enhancement capability | Middle * Enhanced adhesion only at the point of functional group | High * Enhanced adhesion over the whole substrate surface | High * Enhanced adhesion over the whole substrate surface | |

| Film thickness | < 5Å/1500rpm | 5Å/1500rpm | 3nm/1500rpm | |

| Film forming method | Spin coting | 〇 | 〇 | 〇 |

| Vapor Deposition | 〇 | × | × | |

| Bake temperature | 80°C~ | 140°C~ | 120°C~ | |

| Stripping method | O2 ashing | O2 ashing~ | O2 ashing | |

| Substrate compatibility | Si | 〇 | 〇 | 〇 |

| Compound semiconductor | × | 〇 | 〇 | |

| Glass | × | △ | 〇 | |

| Effect of canceling substrate roughness | × | × | 〇 | |

| Wet etching resistance(Cr) | × | × | 〇 | |

OAP (HMDS)

OAP (HMDS) treatment of substrates with hydrophilic (-OH) groups allows for a simple hydrophobic treatment with silylation.

It can be used in photolithography to improve the adhesion between the substrate and the photoresist.

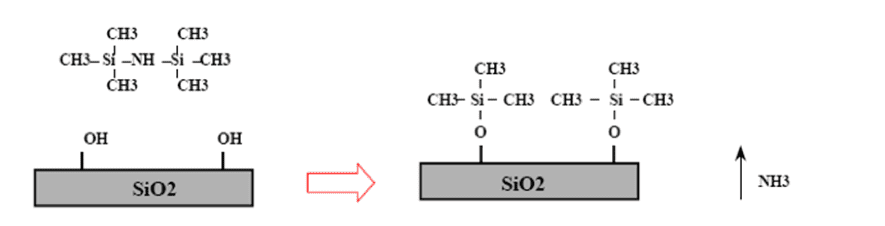

HMDS Treatment

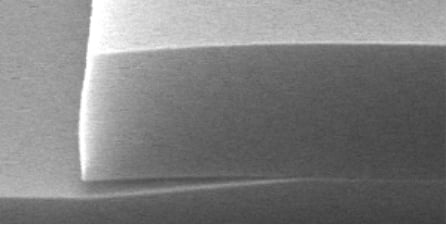

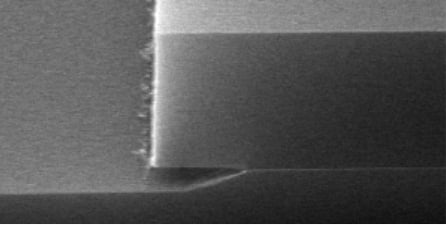

HMDS treatment of hydrophilic surfaces on silicon substrates and SiO films that incorporate OH groups improves resist adhesion by trimethylsilylating the substrate interface. It is possible to prevent resist pattern collapse during development and reduce the amount of side etching during wet etching.

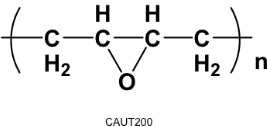

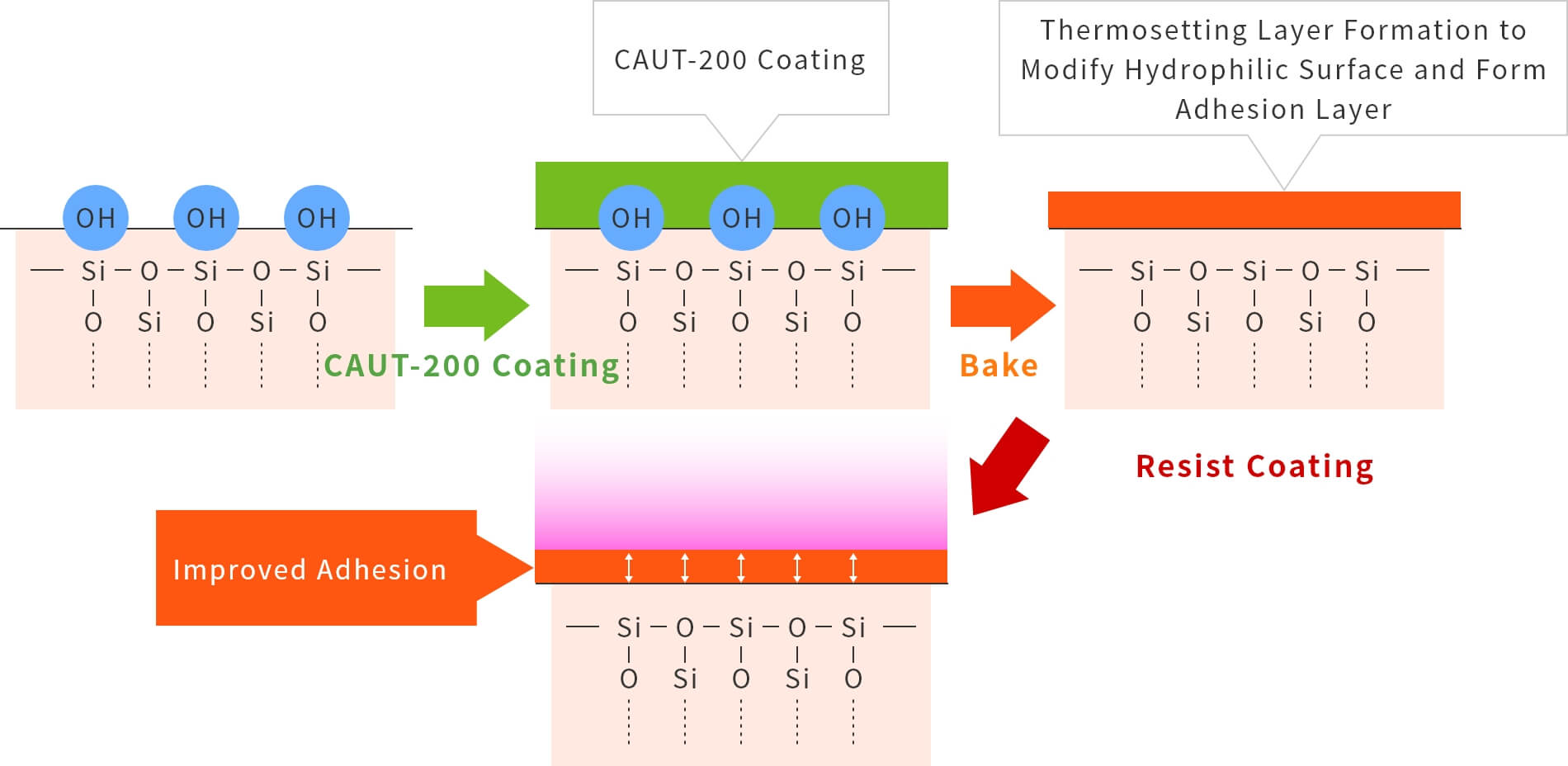

CAUT-200

CAUT-200 Is Designed to Improve Adhesion Between Substrate and Photoresist by Modifying the Hydrophilic Wafer Surface

CAUT-200 is a coating material that improves the adhesion between the base and top layers when forming multilayer structures.

By applying and baking CAUT-200 as a pretreatment for the top layer material on the base layer film (or substrate), CAUT-200 will form an organic layer of several nm on the surface of the base layer and improve the adhesion between the base layer film (substrate) and the top layer material.

Concept for Improving Adhesion

Epoxy polymers are applied on the coated surface and bonded to the substrate surface by thermal reflow.

Please Feel Free to Contact Us for More Information

For any questions or concerns,

Send an Inquiry Through the Web

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.