Development of High Heat Resistance, High Transparency Microlens Resists Using Novel Polymer

What Is an Image Sensor?

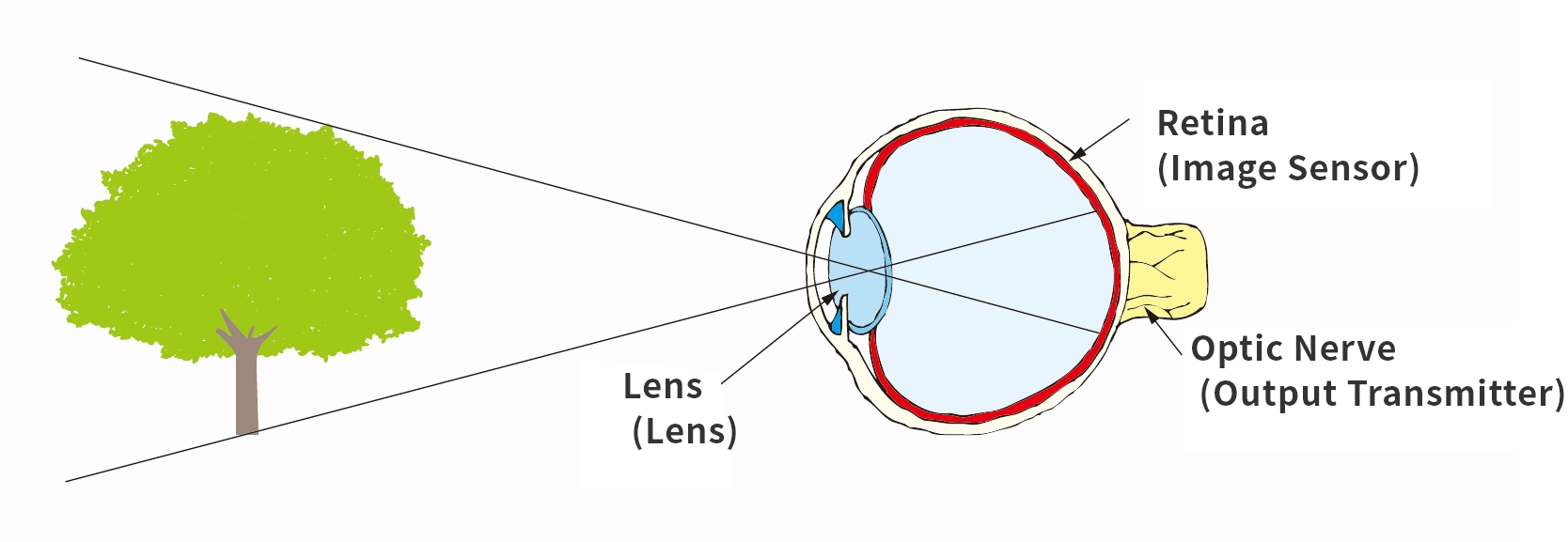

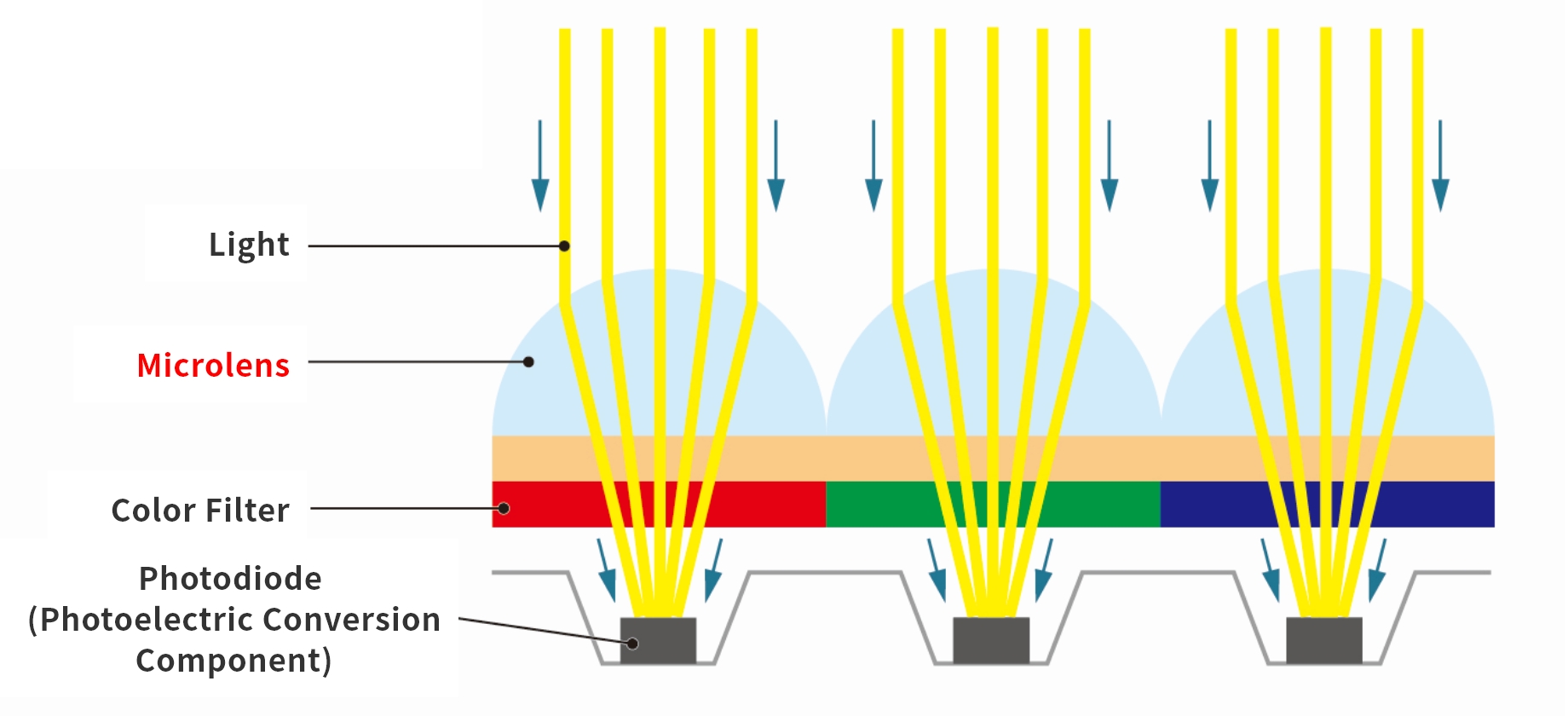

In compact cameras and smartphones, semiconductor component known as image sensors are used to achieve high image quality in the camera. An image sensor is a component similar to the retina found in human eyes (Fig. 1). Light is collected by a microlens on the light receiving surface of this sensor and passed through a color filter into a photodiode (Fig. 2). The photodiode then converts the light (light signal) of the image through the color filter into an electrical signal. By outputting this electrical signal, a digital image is projected. Microlens resists, such as those produced at TOK, are widely used in various fields such as in medical devices and car cameras.

Fig. 1 - The Human Eye

Fig. 2 - Image Sensors

Microlens are an integral part of image sensors, which convert light and dark into electrical signals, improving the efficiency of light collection from external sources. Various manufacturers of image sensors make microlenses using our photoresists. Microlenses are formed by applying photoresist, exposing it, developing it, forming a rectangular resist pattern, and then applying heat to change the lens shape from rectangular to semicircular.

As devices become increasingly small with higher pixel counts, microlens resists are required to be designed at higher definition, and we are continuing our research and development to meet these requirements.

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.