Thinners

There are several types of thinner for various purposes, ranging from specific to multi-functional.

We have specialized rinses for developer and stripper thinners. For back and edge rinsing, we have OK73 thinner™, LA95 thinner, etc. For pipe cleaning, we have SWK™ thinner, NMP thinner, γ-butyl lactone, etc. For pre-wetting, we have VFR™ thinner, ONNR20 thinner, n-butyl acetate, etc.

VFR™ thinner and other resist solvents are available for rework applications.

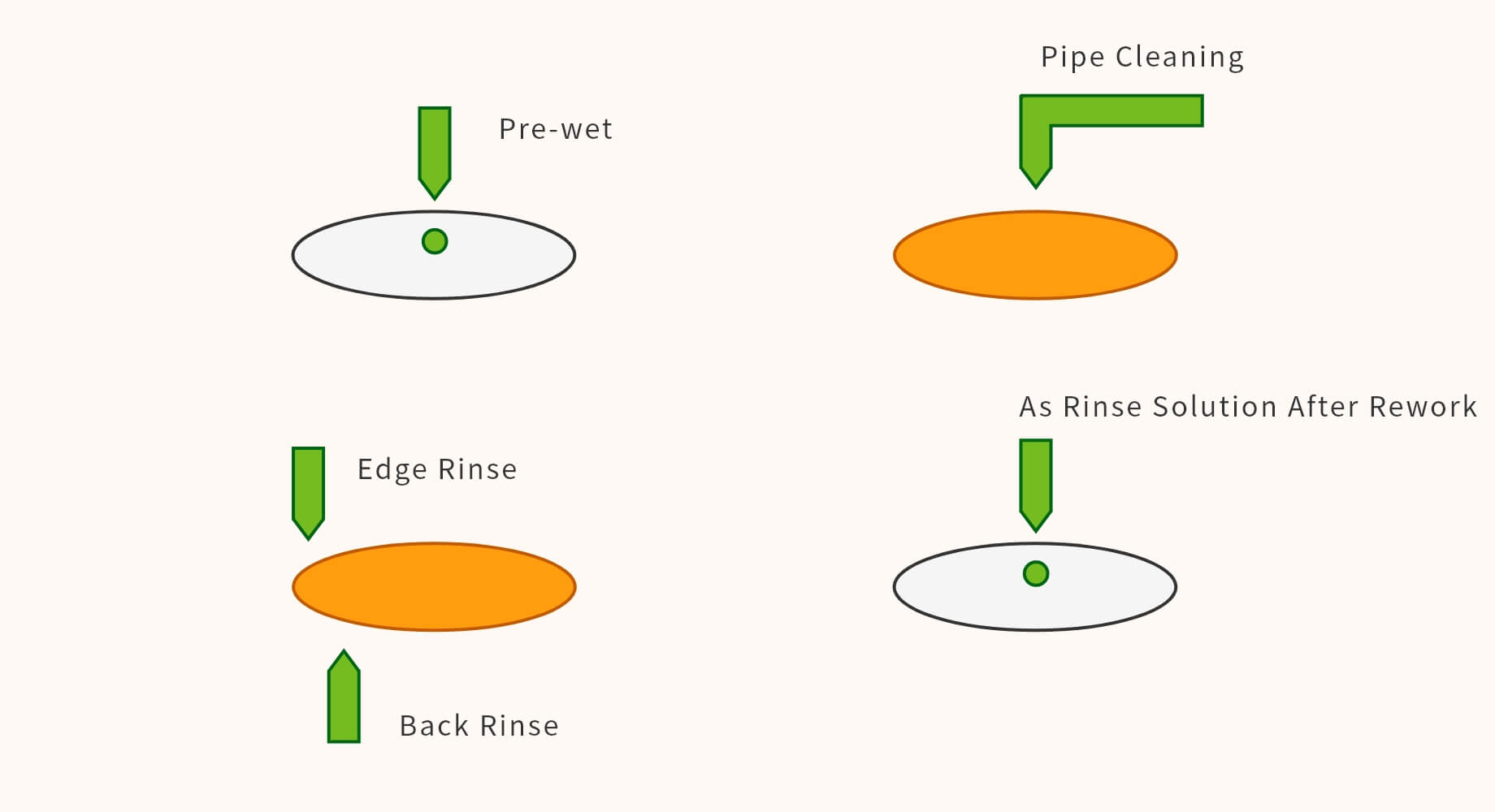

Purpose for Using Thinner

OK73 Thinner™

Thinner for Positive Photoresist

OK73 Thinner™ is a safe photoresist thinner with excellent cleaning properties.

- Applications

- Cleaning of photoresist wafer edges, back surface cleaning, and coater cup cleaning.

OK73 Thinner™ Effects

Resist THMR™-iP3100 Film Thickness: 1μm Pre-bake: 90℃, 90sec

Edge Rinse 50cc/min, 0.6kg/cm2 Back Rinse 100cc/min, 0.6kg/cm2

| Dissolution Time | Edge Rinse | Back Rinse |

|---|---|---|

| OK73 Thinner™ (1.4 sec) |

|

|

| OFPR™800 Thinner (1.6 sec) |

|

|

| MMP Thinner (0.7 sec) |

|

|

| PGMEA (2.5sec) |

|

|

| PGME (1.0sec) |

|

|

VFR™ Thinner

Thinner for Positive Photoresist

VFR™ is a thinner with excellent cleaning properties.

VFR™ Thinner Performance

Cleaning Performance

Each Resist 100℃ bake

Thinner 500rpm, 20sec; rotary drying 3000rpm, 10sec

| Initial Film Thickness | ArF 1.52μm | KrF 4.36μm | I-Line 4.46μm |

|---|---|---|---|

| OK73 Thinner™ | 1.32μm | 0.00μm | 0.01μm |

| VFR™ Thinner | 0.12μm | 0.17μm | 1.09μm |

Residual film after treatment is measured against the initial film thickness.

Pre-wet Performance

| Thinner | Not Used | Pre-wetting | Difference in Resist Drip Volume |

|---|---|---|---|

| OK73 Thinner™ | 3.0cc | 2.5cc | 0.5cc |

| VFR™ Thinner | 0.9cc | 2.1cc |

*The difference in resist (OFPR-800) dripping with and without pre-wetting is measured.

Rework Performance

*In the event that a failure occurs during the resist coating, exposure and development process due to processing conditions or equipment failure (e.g. error in design dimensions, etc.), the existing resist film is removed from the semiconductor substrate and a new coat of resist is applied and the exposure and development process is performed.

Thinner Dripping 1000 rpm/30sec Rotational Drying 3000 rpm/10sec

Resist Film Thickness 1μm Pre-bake 110℃, 90sec

| 1ml | 2ml | 3ml | 4ml | |

|---|---|---|---|---|

| OFPR-800 |  × |

× |

× |

○ |

| TSCR-120i |  × |

× |

○ |

○ |

*Observe the residue from changing the drip volume of thinner (VFR).

OK73 Thinner, VFR, OFPR, and TSCR in the text are a pending or registered trademarks of TOK.

Please Feel Free to Contact Us for More Information

For any questions or concerns,

Send an Inquiry Through the Web

Contact Us/Download Information

Please contact us if you have any requests or problems.

You can also access information related to each product.